- North America dominated the market with the largest market share of 38% in 2023.

- Asia Pacific is expected to witness the fastest CAGR of 8.62% between 2024 and 2033

- By type, the accelerometers segment has captured more than 45% in 2023.

- By type, the displacement sensors segment is expected to expand at a CAGR of 8.4% between 2024 and 2033.

- By technology, the piezoresistive sensors segment has generated 25% of market share in 2023.

- By technology, the tri-axial sensors segment is projected to grow at the fastest CAGR of 8.92% between 2024 and 2033.

- By end-use, the automobile segment has held the significant market share of 28% in 2023.

- By material, the quartz-based sensors segment has recorded more than 44% of the market share in 2023.

Get a Sample: https://www.precedenceresearch.com/sample/3969

Growth Factors:

Several key factors have contributed to the growth of the vibration sensor market. Firstly, the increasing adoption of Industry 4.0 and IoT (Internet of Things) technologies has led to a surge in demand for sensors capable of monitoring machine health and performance in real-time. Vibration sensors, when integrated into smart manufacturing systems, enable predictive maintenance strategies by providing actionable insights into equipment condition and performance, thereby optimizing maintenance schedules and reducing overall maintenance costs.

Moreover, stringent regulations and standards mandating the implementation of condition monitoring and predictive maintenance practices across industries such as manufacturing, automotive, aerospace, and energy have driven the adoption of vibration sensors. Compliance with these regulations requires the implementation of advanced monitoring systems to ensure equipment safety, reliability, and compliance with performance standards, thereby fueling market growth.

Additionally, the growing focus on operational efficiency, productivity, and asset optimization has spurred the demand for vibration sensors in various industrial applications. By detecting anomalies and abnormalities in machinery vibrations, these sensors enable early detection of potential faults or failures, allowing operators to take proactive measures to address issues before they escalate into costly downtime or equipment damage.

Furthermore, technological advancements in sensor design, miniaturization, and wireless connectivity have expanded the applicability of vibration sensors across a wide range of applications and industries. Miniaturized sensors with wireless capabilities offer flexibility in installation, reduced maintenance requirements, and seamless integration with existing automation and monitoring systems, driving adoption in diverse industrial environments.

Region Insights:

The adoption of vibration sensors varies across regions, influenced by factors such as industrialization, technological advancements, and regulatory frameworks. In North America, the United States and Canada lead the market for vibration sensors, driven by the presence of a robust manufacturing sector, increasing investments in industrial automation, and the adoption of advanced monitoring technologies. The region’s focus on innovation and technological leadership has led to widespread adoption of vibration sensors in various industries, including automotive, aerospace, and manufacturing.

In Europe, countries such as Germany, the United Kingdom, and France are key markets for vibration sensors, owing to the region’s strong industrial base, stringent regulatory requirements, and emphasis on quality and safety standards. The European Union’s directives on machinery safety and industrial emissions control have propelled the adoption of vibration sensors in critical applications such as machine health monitoring, structural health monitoring, and predictive maintenance.

In Asia Pacific, countries like China, Japan, and South Korea are witnessing significant growth in the vibration sensor market, driven by rapid industrialization, infrastructure development, and increasing investments in smart manufacturing technologies. The region’s burgeoning automotive, electronics, and manufacturing sectors are driving demand for vibration sensors to enhance production efficiency, ensure product quality, and minimize downtime.

In Latin America and the Middle East, industrial growth and infrastructure development initiatives are driving demand for vibration sensors in sectors such as oil and gas, mining, and construction. The adoption of vibration sensors in these regions is supported by government initiatives to improve workplace safety, enhance operational efficiency, and comply with industry regulations and standards.

Vibration Sensor Market Scope

| Report Coverage | Details |

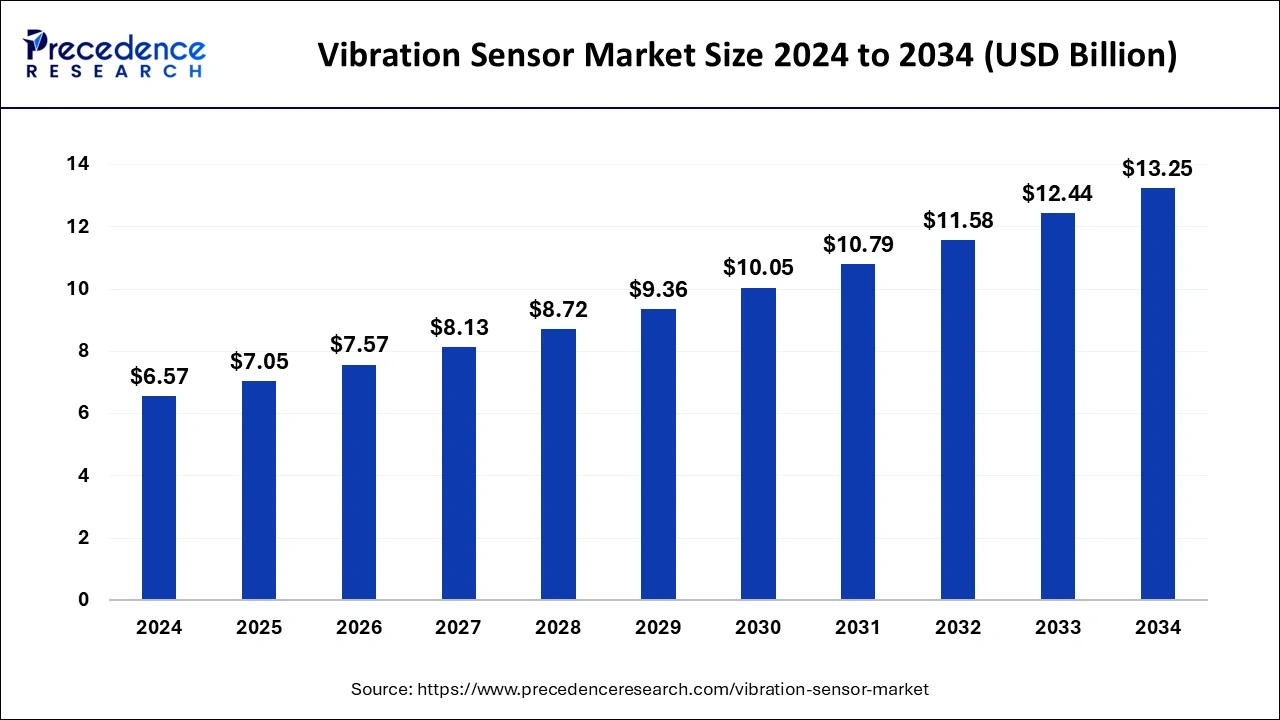

| Growth Rate from 2024 to 2033 | CAGR of 7.35% |

| Global Market Size in 2023 | USD 6.12 Billion |

| Global Market Size by 2033 | USD 12.44 Billion |

| U.S. Market Size in 2023 | USD 1.74 Billion |

| U.S. Market Size by 2033 | USD 3.55 Billion |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Type, By Technology, By End-use, and By Material |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Vibration Sensor Market Dynamics

Drivers:

Several drivers are shaping the growth of the vibration sensor market. One of the primary drivers is the increasing focus on predictive maintenance and condition monitoring strategies to optimize asset performance and reduce maintenance costs. Vibration sensors play a crucial role in predictive maintenance programs by continuously monitoring equipment vibrations and detecting abnormal patterns indicative of potential faults or failures. By identifying issues early, operators can schedule maintenance proactively, minimize downtime, and avoid costly repairs.

Moreover, the growing adoption of IoT and connected technologies in industrial environments is driving demand for vibration sensors with wireless connectivity and remote monitoring capabilities. Integrated with IoT platforms and analytics software, vibration sensors enable real-time monitoring of equipment health and performance, facilitating data-driven decision-making and predictive maintenance strategies.

Furthermore, the need for improved operational efficiency, productivity, and asset utilization is driving investments in vibration monitoring systems across various industries. By providing actionable insights into equipment health and performance, vibration sensors enable operators to optimize maintenance schedules, extend equipment lifespan, and maximize uptime, thereby enhancing overall operational efficiency and profitability.

Additionally, the increasing emphasis on workplace safety and regulatory compliance is driving the adoption of vibration sensors in hazardous environments and critical applications. Vibration sensors help identify potential safety hazards such as equipment malfunctions, structural weaknesses, or excessive vibrations that could compromise worker safety or lead to catastrophic failures. Compliance with industry regulations and safety standards requires the implementation of robust monitoring systems, including vibration sensors, to ensure equipment integrity and mitigate risks.

Furthermore, advancements in sensor technology, including MEMS (Micro-Electro-Mechanical Systems) sensors, piezoelectric sensors, and fiber optic sensors, are expanding the capabilities and applicability of vibration sensors in diverse industrial applications. Miniaturization, improved sensitivity, and ruggedized designs enable vibration sensors to withstand harsh operating conditions, such as high temperatures, corrosive environments, and high shock levels, making them suitable for use in a wide range of industries and applications.

Opportunities:

The vibration sensor market presents numerous opportunities for stakeholders across industries and regions. One of the significant opportunities lies in the adoption of vibration sensors for predictive maintenance and asset management applications. As industries strive to improve operational efficiency, reduce downtime, and optimize maintenance costs, there is a growing demand for advanced monitoring solutions capable of detecting early signs of equipment degradation or failure. Vibration sensors, integrated with predictive analytics software and IoT platforms, offer a proactive approach to maintenance, enabling operators to identify and address potential issues before they impact production or safety.

Moreover, the expansion of industrial automation and smart manufacturing initiatives presents opportunities for the integration of vibration sensors into connected systems and IoT ecosystems. By leveraging sensor data and analytics, manufacturers can gain valuable insights into equipment health, performance trends, and operational inefficiencies, enabling continuous improvement and optimization of production processes.

Furthermore, the increasing focus on asset optimization and lifecycle management is driving demand for vibration sensors in asset-intensive industries such as oil and gas, utilities, and heavy manufacturing. Vibration sensors enable operators to monitor equipment health in real-time, prioritize maintenance activities, and extend the lifespan of critical assets, thereby maximizing return on investment and reducing total cost of ownership.

Additionally, the growing adoption of vibration sensors in emerging markets and sectors such as renewable energy, transportation, and healthcare presents untapped opportunities for market expansion. As these industries embrace digital transformation and IoT technologies, there is a growing need for reliable and cost-effective monitoring solutions to ensure equipment reliability, safety, and compliance with industry standards.

Furthermore, advancements in sensor technology, including improvements in sensitivity, accuracy, and reliability, are opening up new possibilities for innovation and differentiation in the vibration sensor market. Enhanced sensor capabilities, coupled with developments in wireless connectivity, edge computing, and cloud-based analytics, enable the development of integrated monitoring solutions tailored to specific industry needs and application requirements.

Challenges:

Despite the significant growth potential, the vibration sensor market faces several challenges that could impact market growth and adoption. One of the primary challenges is the complexity and diversity of industrial environments, which can present obstacles to sensor deployment and data interpretation. Industrial settings often involve harsh operating conditions, including extreme temperatures, high vibration levels, and exposure to dust, moisture, and corrosive substances, which can affect sensor performance.

Read Also: Cardiac Rhythm Management Devices Market Size, Report by 2033

Recent Developments

- In January 2023, HARMAN International unveiled its sound and vibration sensor and external microphone products, designed to enhance the auditory experience in and around vehicles for various applications, including identifying emergency vehicle sirens and detecting glass breakage or collisions.

- In March 2022, SAMSUNG released the Galaxy A53 5G smartphone, which features an octa-core processor, a 120 Hz refresh rate display, and a sharp resolution of 1080 x 2400 pixels.

- In May 2022, Sensoteq announced the Kappa X Wireless Vibration Sensor. This compact sensor has a replaceable battery and can detect faults, making it suitable for various industrial applications.

Vibration Sensor Market Companies

- Dytran Instruments, Inc.

- PCB Piezotronics, Inc. (IMI Sensors division)

- Hansford Sensors Ltd.

- TE Connectivity Ltd. (formerly Measurement Specialties, Inc.)

- Honeywell International Inc.

- Robert Bosch GmbH

- National Instruments Corporation

- Analog Devices, Inc.

- Meggitt PLC

Segment Covered in the Report

By Type

- Accelerometers

- Velocity Sensors

- Displacement Sensors

By Technology

- Piezoresistive Sensors

- Tri-Axial Sensors

By End-use

- Automotive Sector

- Aerospace And Defense

- Consumer Electronics

By Material

- Quartz-based Sensors

- Doped Silicon Sensors

- Piezoelectric Ceramics

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/