- Asia Pacific dominated the market in 2023 with the largest share 35%.

- North America is anticipated to grow at a notable growth rate in the wind turbine composite materials market during the forecast period.

- By fiber type, the glass fiber segment held the largest share of around 65% in 2023.

- By fiber type, the carbon fiber segment is expected to grow significantly during the forecast period.

- By technology, the vacuum injection molding segment accounted for the dominating share of 45% in 2023.

- By technology, the prepreg segment is observed to witness a considerable growth rate in the global wind turbine composite materials market over the forecast period.

- By application, the wind blades segment held the dominating share of 75% in 2023

Get a Sample: https://www.precedenceresearch.com/sample/4067

Wind Turbine Composite Materials Market Scope

| Report Coverage | Details |

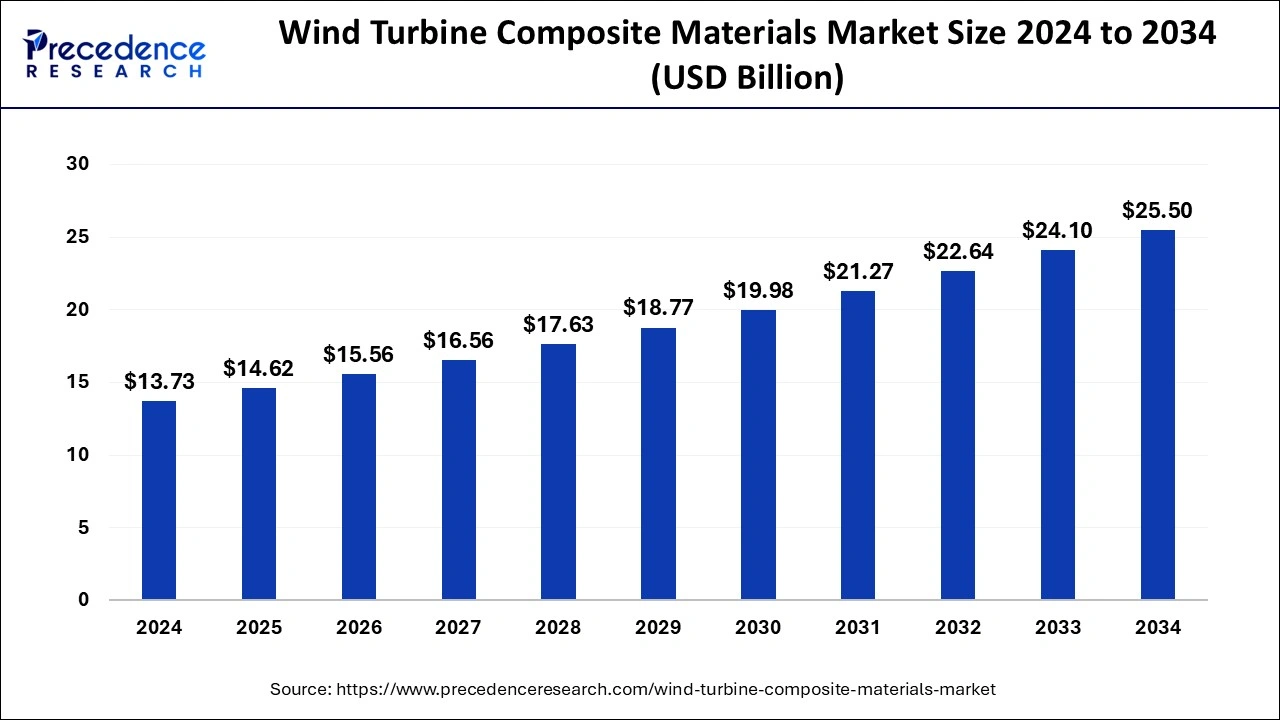

| Growth Rate from 2024 to 2033 | CAGR of 6.44% |

| Global Market Size in 2023 | USD 12.90 Billion |

| Global Market Size in 2024 | USD 13.73 Billion |

| Global Market Size by 2033 | USD 24.10 Billion |

| Largest Market | Asia-Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Fiber Type, By Technology, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

One of the primary composite materials used in wind turbine blades is fiberglass reinforced polymers (FRP). These materials consist of fiberglass fibers embedded in a polymer matrix, typically epoxy or polyester resin. The fiberglass provides strength and stiffness, while the polymer matrix protects the fibers from environmental degradation and provides structural integrity. FRP composites offer a high strength-to-weight ratio, making them ideal for large-scale wind turbine blades where weight reduction is critical for efficient operation.

Carbon fiber reinforced polymers (CFRP) are also used in wind turbine blade construction, particularly in high-performance applications where superior strength and stiffness are required. Carbon fibers are known for their exceptional mechanical properties, including high tensile strength and stiffness, as well as resistance to fatigue and corrosion. CFRP composites offer advantages in terms of weight reduction and design flexibility, allowing for the production of longer and more aerodynamically efficient wind turbine blades.

In addition to blade construction, composite materials are also used in other components of wind turbines, such as nacelles and towers. Nacelles, which house the generator, gearbox, and other critical components, often utilize composite materials for their lightweight yet durable properties. Composite towers, constructed from fiberglass or carbon fiber, offer advantages in terms of ease of transportation, assembly, and resistance to corrosion compared to traditional steel towers.

The adoption of composite materials in wind turbine construction has led to significant advancements in turbine design, performance, and cost-effectiveness. By utilizing lightweight and durable composites, wind turbines can capture more wind energy, operate more efficiently, and have a longer service life. Furthermore, composite materials enable the production of larger and more powerful turbines, which can generate higher levels of electricity and contribute to the expansion of renewable energy capacity.

However, the use of composite materials in wind turbine construction also presents challenges, particularly in terms of manufacturing processes, recycling, and end-of-life disposal. The production of composite materials requires specialized equipment and expertise, which can increase manufacturing costs and lead times. Additionally, the recycling of composite materials poses challenges due to the complex nature of composite structures and the separation of different materials for recycling.

Efforts are underway to develop innovative recycling technologies and sustainable manufacturing processes to address these challenges and reduce the environmental impact of wind turbine composites. Research and development initiatives focus on improving the recyclability of composite materials, exploring alternative manufacturing methods, and optimizing material usage to minimize waste.

Overall, wind turbine composite materials play a crucial role in enabling the widespread adoption of wind energy as a clean and renewable source of electricity. By providing lightweight, durable, and cost-effective solutions for wind turbine construction, composite materials contribute to the growth of the wind energy industry and the transition to a more sustainable energy future. Continued research and innovation in composite materials technology will further enhance the performance, reliability, and environmental sustainability of wind turbines in the years to come.

Read Also: Data Center Transformation Market Size, Share, Report by 2033

Recent Developments

- According to a BSE filing, in June 2023, SJVN Green Energy, a subsidiary of SJVN Ltd, secured a 200 MW wind power project through a tariff-based competitive bidding process conducted by the Solar Energy Corporation of India. This project requires an investment of Rs 1,400 crore. SJVN Green Energy will undertake the development of this wind power project anywhere in India through an EPC (engineering procurement construction) contract.

- Amazon now has more than 500 wind and solar projects globally, and once operational, they are expected to generate more than 77,000 gigawatt-hours (GWh) of clean energy each year, or enough to power 7.2 million U.S. homes.

Wind Turbine Composite Materials Market Companies

- TPI Composites Inc.

- Huntsman International LLC

- Teijin Limited

- TPI Composites Inc.

- LM Wind Power

- Suzlon Energy Limited

- Gurmit Holding AG

- LM Wind Power

- Molded Fiber Glass Companies

- Toray Industries, Inc.

- Vestas Wind Systems A/S

- Siemens Gamesa Renewable Energy, S.A.U.

- Hexcel Corporation

- Lianyungang Zhongfu Lianzhong Composites Group Co. Ltd

- Others

Segments Covered in the Report:

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Others

By Technology

- Vacuum Injection Molding

- Prepreg

- Hand Lay-Up

- Others

By Application

- Wind blades

- Nacelles

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/