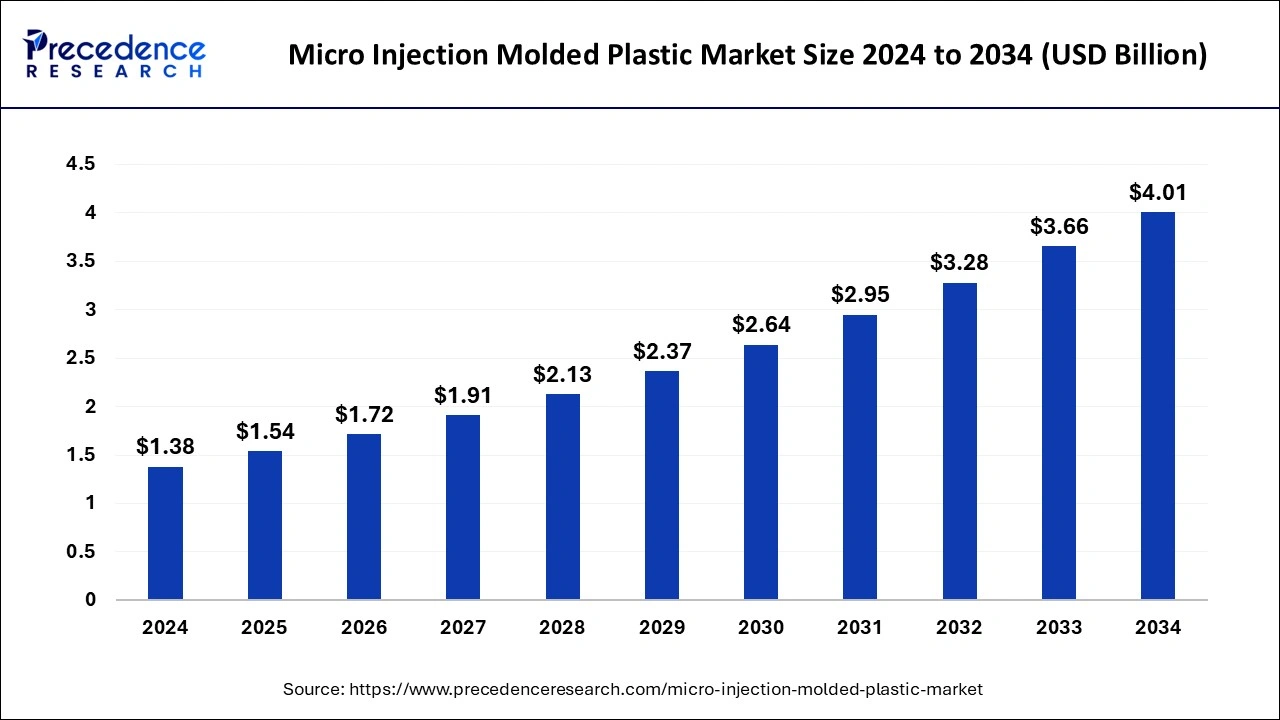

The global micro injection molded plastic market size reached USD 1.24 billion in 2023 and is projected to surpass around USD 3.66 billion by 2033. at a solid CAGR of 11.42% over the forecast period 2024 to 2033.

Key Points

- Asia Pacific held the largest share of the market in 2023.

- North America is expected to be the fastest growing in the market during the forecast period.

- By material, the polycarbonate (PC) segment dominated the market in 2023.

- By material, the polyethylene (PE) segment is the fastest-growing during the forecast period.

- By application, the medical and healthcare segment dominated the micro injection molded plastic market in 2023.

- By application, the automotive segment is the fastest-growing during the forecast period.

The micro injection molded plastic market is experiencing significant growth driven by expanding applications across various industries such as medical devices, electronics, automotive, and consumer goods. This technology enables the production of intricate and small components with high precision and repeatability, crucial for industries demanding miniaturization and complex geometries. Key factors contributing to market growth include advancements in material science, increasing demand for miniaturized electronic components, and rising adoption of micro components in medical devices for minimally invasive procedures. Geographically, North America and Asia Pacific are prominent regions due to the presence of key manufacturers and high demand across diverse end-use sectors. The market is characterized by ongoing innovations in materials, technologies, and manufacturing processes aimed at enhancing product performance and reducing production costs.

Get a Sample: https://www.precedenceresearch.com/sample/4564

Table of Contents

ToggleMarket Drivers

The Micro Injection Molded Plastic Market is driven primarily by the increasing demand for miniaturized components across various industries such as electronics, medical devices, automotive, and consumer goods. These components require precise molding techniques to achieve high levels of accuracy and consistency in manufacturing. Technological advancements in micro molding processes, including improvements in mold design and materials, are further boosting market growth. Additionally, the trend towards lightweighting and miniaturization in product designs is fueling the adoption of micro injection molded plastics, as they offer superior strength-to-weight ratios and cost-effectiveness compared to traditional manufacturing methods.

Market Challenges

Despite its growth prospects, the Micro Injection Molded Plastic Market faces several challenges. One significant challenge is the complexity of molding extremely small and intricate parts with high precision. Achieving uniformity and quality in micro parts production requires sophisticated equipment and meticulous process control, which can drive up initial setup costs. Moreover, the selection of suitable materials for micro molding applications remains a challenge, as these materials must exhibit excellent flow characteristics, dimensional stability, and mechanical properties at reduced scales. Furthermore, regulatory compliance and quality assurance standards in industries like healthcare and automotive impose stringent requirements on micro molded components, adding to the complexity and cost of production.

Market Opportunities

The Micro Injection Molded Plastic Market presents compelling opportunities driven by advancements in material science and molding technologies. Emerging applications in sectors such as healthcare, where miniaturized medical devices and drug delivery systems are in high demand, are expanding the market scope. Moreover, the growing adoption of micro molding in consumer electronics for producing small, complex components like connectors, sensors, and microfluidic devices offers substantial growth opportunities. Additionally, the trend towards customization and personalized products is driving demand for micro injection molded plastics, as manufacturers can cater to niche market needs with tailored solutions. Furthermore, ongoing research and development efforts focused on enhancing mold designs, optimizing materials, and improving process efficiency are expected to unlock new avenues for market expansion in the coming years.

Micro Injection Molded Plastic Market Scope

| Report Coverage | Details |

| Market Size by 2033 | USD 3.66 Billion |

| Market Size in 2023 | USD 1.24 Billion |

| Market Size in 2024 | USD 1.38 Billion |

| Market Growth Rate from 2024 to 2033 | CAGR of 11.42% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Material, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Read Also: Genome Editing Market Size to Surpass USD 38.19 Bn by 2033

Materials Used Insights

Micro injection molded plastics utilize a range of materials tailored to meet specific performance requirements across different applications. Engineering plastics such as ABS, PC, and PEEK are favored for their high strength, heat resistance, and dimensional stability, making them suitable for components in electronics, automotive, and medical devices where durability and precision are critical. Thermoplastic elastomers (TPE), including TPU and TPE-S, offer flexibility and elasticity, ideal for applications needing soft touch and impact resistance, such as consumer goods and medical instruments. Bio-based plastics like PLA and PHA are gaining traction due to their sustainability benefits, appealing to industries seeking environmentally friendly solutions. High-performance plastics such as PPS and LCP provide excellent chemical resistance and thermal stability, essential for demanding applications in automotive and telecommunications sectors.

Applications Insights

The versatility of micro injection molded plastics is evident in their widespread applications across various industries. In electronics, these materials are integral to miniaturized components like connectors, sensor housings, and micro switches used in smartphones, wearables, and IoT devices. Medical devices benefit from micro molded plastics in the production of microfluidic chips, surgical instruments, and drug delivery systems, where biocompatibility and precision are paramount. Automotive applications include micro valves, sensor components, and interior trim parts, contributing to vehicle efficiency and performance enhancements. Consumer goods utilize micro injection molded plastics for miniature gears, buttons, cosmetic packaging, and compact housings, improving product aesthetics and functionality. Telecommunications sectors rely on these materials for fiber optic connectors, micro antennas, and telecommunications modules to support high-speed data transmission and network infrastructure reliability.

Regional Insights

The micro injection molded plastic market shows significant regional variation in demand and growth. North America and Europe lead in adoption, driven by robust healthcare and automotive sectors demanding precise and small-sized components. Asia-Pacific is poised for rapid growth, fueled by expanding industrial and consumer electronics sectors in countries like China, Japan, and South Korea. Meanwhile, Latin America and the Middle East & Africa regions are experiencing gradual uptake, with increasing investments in manufacturing capabilities and rising consumer goods demand contributing to market expansion.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/customization/4564

Micro Injection Molded Plastic Market Companies

- Rapidwerks

- BMP Medical

- Makuta Techniques Inc.

- Sil-Pro LLC

- MTD Micro Molding

- Isometric Micro Molding, Inc.

- 3M

- Precikam Inc

- Spectrum Plastics Group, Inc.

- SMC Ltd

- Paragon Medical

- Accumold LLC

- Knightsbridge Plastics Inc.

- D&M Plastics LLC

- Microsystems UK

- Microdyne Plastics Inc

- Sovrin Plastics

- Stack Plastics

- YOMURA TECHNOLOGIES, INC.

- WITTMAN Technology GmbH

Recent Developments

- In August 2022, LS Injection Molding Machines launched a new AI (Artificial Intelligence)-based smart injection molding system. The new technology characterizes two systems, the Smart Weight Control and AI Molding Assistant. It will help holders to achieve faster deliveries, higher productivity, reduced costs, improved part quality, and customer satisfaction.

- In May 2023, the leading vertically integrated contract manufacturer for the interventional medical device market, Biomerics, announced a merger with Precision Concepts Medical. Precision Concepts Medical offers capabilities for the micro-assembly process, injection micro molding process, micro metals stamping, and machining.

- In July 2023, a 100% recycled 3D printing material, dubbed Windform XT 2.0 IMG, injection molding grade, was launched by a 3D printing materials and services provider CRP Technology. This material is suitable for high-grade injection molded components and applications found in sectors like industrial design, robotics, agriculture, e-mobility, transportation, and automotive.

- In November 2023, the FANUC and Milacron drive to provide the best-in-class all-electric injection molding solutions. The results are extremely short cycle times, ultimate precision of movement, greater acceleration, and the ability to produce the highest quality and most consistent parts.

- In January 2024, FUSO authorized an ultra-modern machine technology for the production of cost-efficient and sustainable injection molded solutions for diverse industries like renewable energy generation, mechanical engineering, telecommunication, building construction, medical technology, electronics, consumer goods, automotive, and railway industries.

Segments Covered in the Report

By Material

- Liquid-crystal Polymer (LCP)

- Polyether Ether Ketone (PEEK)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polyoxymethylene (POM)

- Others

By Application

- Medical & Healthcare

- Automotive

- Electronics

- Telecommunications

- Aerospace and Defense

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/