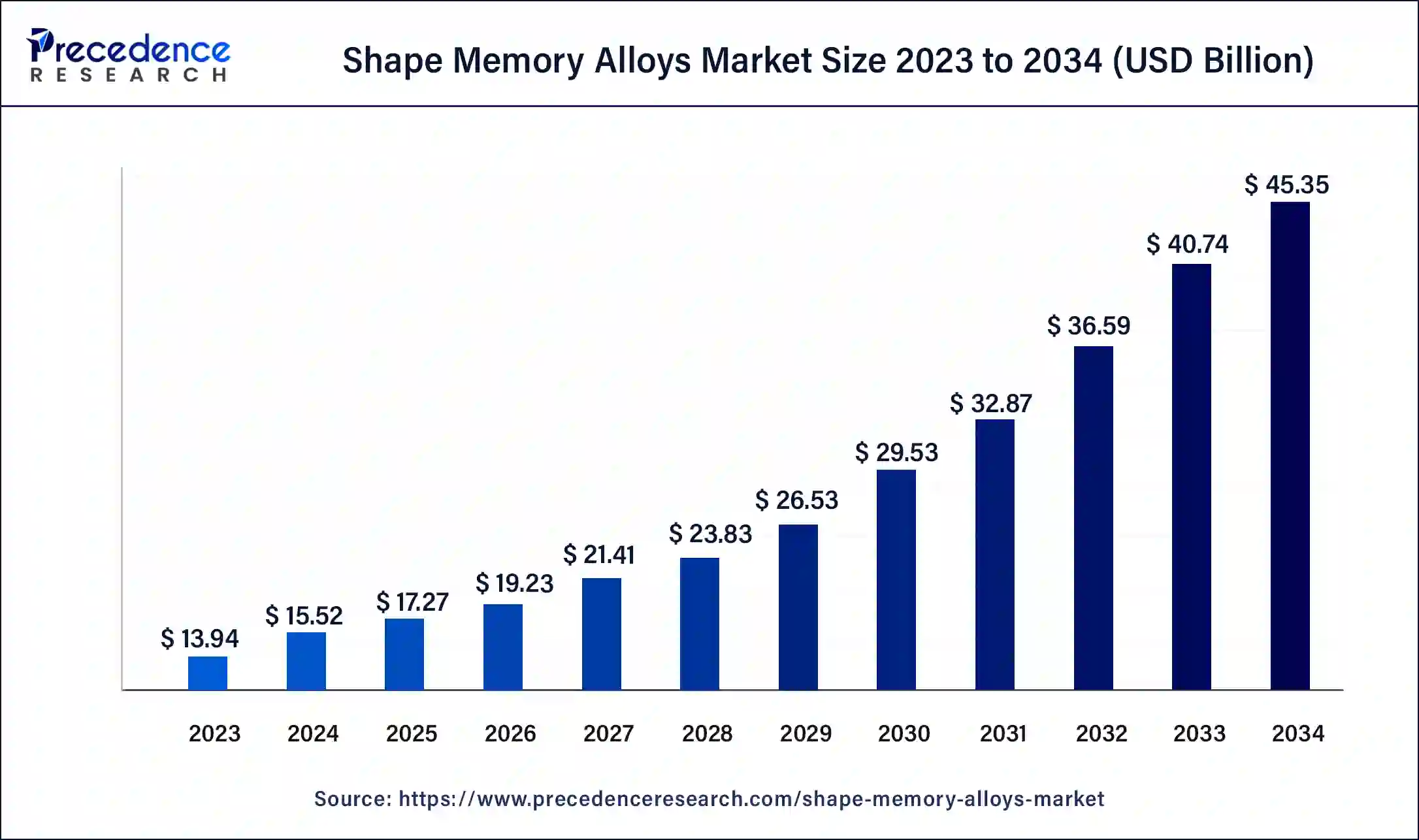

The global shape memory alloys market size reached USD 13.94 billion in 2023 and is predicted to cross around USD 45.35 billion by 2034 with a CAGR of 11.32% from 2024 to 2034.

These are metallic alloys that, when subjected to external stimuli like mechanical stress or temperature changes, can revert to their original size or shape. Eversible martensitic phase transitions are the source of these remarkable characteristics. Because of their extreme elasticity, shape memory alloys are useful in a variety of fields, including consumer electronics, automobile components, aerospace engineering, and medical devices. Because these alloys have unique properties, they are also used in a variety of applications. The market for shape memory alloys provides flexibility, adaptability, and dependability to a wide range of diverse industries.

Get a Sample: https://www.precedenceresearch.com/sample/4842

Shape Memory Alloys Import/export volumes 2020 to 2023

Import Volume (in tons)

| Year | United States | Canada | Germany | France | UK | China | Japan | South Korea | India | Brazil | Mexico | UAE | South Africa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2020 | 5,000 | 800 | 4,000 | 1,500 | 1,200 | 6,000 | 2,800 | 1,500 | 1,000 | 600 | 1,200 | 500 | 400 |

| 2021 | 5,300 | 850 | 4,200 | 1,600 | 1,250 | 6,600 | 3,000 | 1,600 | 1,100 | 620 | 1,300 | 520 | 420 |

| 2022 | 5,600 | 900 | 4,500 | 1,700 | 1,300 | 7,200 | 3,200 | 1,700 | 1,200 | 650 | 1,400 | 550 | 440 |

| 2023 | 5,900 | 950 | 4,800 | 1,800 | 1,350 | 7,800 | 3,400 | 1,800 | 1,300 | 680 | 1,500 | 580 | 460 |

Export Volume (in tons)

| Year | United States | Canada | Germany | France | UK | China | Japan | South Korea | India | Brazil | Mexico | UAE | South Africa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2020 | 3,200 | 500 | 3,000 | 1,200 | 900 | 4,500 | 2,000 | 1,200 | 700 | 400 | 900 | 300 | 250 |

| 2021 | 3,400 | 550 | 3,200 | 1,300 | 950 | 5,000 | 2,200 | 1,300 | 750 | 420 | 950 | 320 | 270 |

| 2022 | 3,600 | 600 | 3,400 | 1,400 | 1,000 | 5,500 | 2,400 | 1,400 | 800 | 440 | 1,000 | 340 | 290 |

| 2023 | 3,800 | 650 | 3,600 | 1,500 | 1,050 | 6,000 | 2,600 | 1,500 | 850 | 460 | 1,050 | 360 | 310 |

Growth Rate (Annual %)

| Region | Growth Rate (2020-2023) |

|---|---|

| United States | 5-7% |

| Canada | 4-6% |

| Germany | 6-8% |

| France | 5-7% |

| UK | 5-7% |

| China | 8-10% |

| Japan | 6-8% |

| South Korea | 7-9% |

| India | 5-7% |

| Brazil | 3-5% |

| Mexico | 5-6% |

| UAE | 4-6% |

| South Africa | 3-5% |

This chart captures the changes in import and export volumes for Shape Memory Alloys across different regions over the specified years.

Nickel-Titanium Alloys (Nitinol)

- Composition: A near-equal mix of nickel and titanium.

- Properties: Known for its high ductility, corrosion resistance, and biocompatibility, Nitinol is the most common type of SMA.

- Applications: Widely used in medical devices like stents, guidewires, and orthodontic archwires. It’s also used in aerospace and robotics.

Copper-Based Alloys

- Subtypes:

- Copper-Zinc-Aluminum (CuZnAl): Consists of copper, zinc, and aluminum.

- Copper-Aluminum-Nickel (CuAlNi): Contains copper, aluminum, and nickel.

- Properties: These alloys have a lower cost compared to Nitinol but typically exhibit lower transformation temperatures and mechanical properties.

- Applications: Used in less demanding applications like temperature control systems, actuators, and sensors.

Iron-Based Alloys

- Subtypes:

- Iron-Manganese-Silicon (FeMnSi): A combination of iron, manganese, and silicon.

- Iron-Nickel-Titanium (FeNiTi): Includes iron, nickel, and titanium.

- Properties: Iron-based SMAs tend to be more brittle but are also cheaper. They are suitable for applications that require less precision in terms of mechanical properties.

- Applications: Used in applications such as pipe fittings, fastening devices, and structural reinforcements.

Gold-Cadmium (AuCd)

- Composition: A mix of gold and cadmium.

- Properties: Exhibits shape memory behavior at higher temperatures but is less commonly used due to the rarity and toxicity of cadmium.

- Applications: Rarely used today due to environmental and health concerns.

Silver-Cadmium (AgCd)

- Composition: A combination of silver and cadmium.

- Properties: Similar to gold-cadmium but less commonly used due to toxicity and environmental concerns.

- Applications: Limited use, primarily in research.

Other Emerging Alloys

- Researchers are constantly developing new SMAs that offer enhanced properties such as higher strength, better fatigue resistance, or the ability to function at different temperature ranges. Examples include alloys based on magnesium, zinc, and other metals.

Production of Shape Memory Alloys Market

| Region | Key Countries | Major Companies | Primary Applications | Production Trends |

| North America | United States, Canada | Fort Wayne Metals, ATI Specialty Alloys | Aerospace, medical devices, automotive | Leading production, high demand in aerospace and healthcare |

| Europe | Germany, France, UK | SAES Getters, Euroflex GmbH, Aperam | Robotics, automotive, medical devices | Strong in automotive and aerospace, focus on innovation |

| Asia-Pacific | China, Japan, South Korea | Furukawa Electric, Nippon Steel | Robotics, electronics, automotive | Rapid growth, major focus on electronics and automotive |