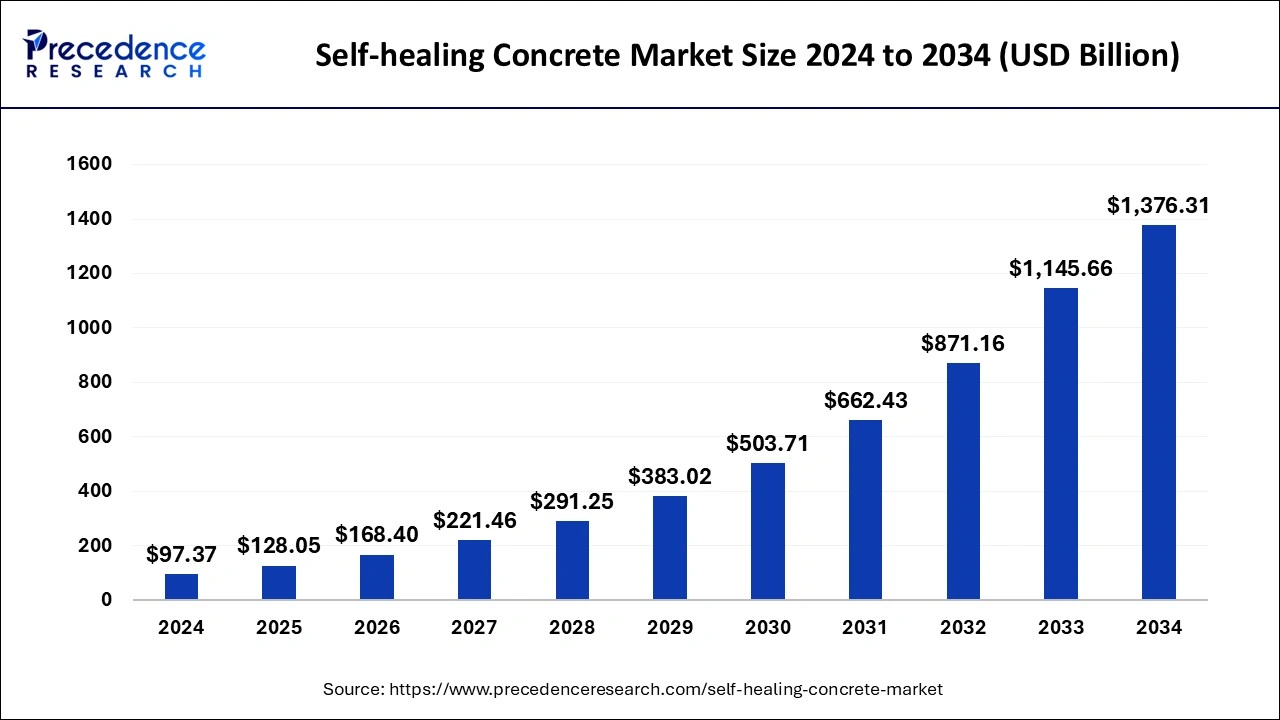

The global self-healing concrete market size reached USD 74.04 billion in 2023 and is predicted to achieve around USD 1,145.66 billion by 2033, at a CAGR of 31.51% from 2024 to 2033.

Self-healing concrete is a type of innovative concrete designed to repair cracks autonomously that form over time. The self-healing concrete market is rapidly growing due to several reasons. The advanced material incorporates healing agents, such as bacteria, capsules, or other chemical compounds, which activate upon crack formation.

Self-healing concrete is a sustainable and ecologically friendly material that can mend its cracks autonomously, partially or totally, restoring the mechanical qualities of structural parts. This is due to concrete’s poor condition, which commonly leads to surface fissures that impair its durability. Self-healing concrete can be improved by including admixtures such as crystalline admixtures, mineral additions, and superabsorbent polymers. It may also have built-in self-sufficient self-healing strategies such as capsule-based, vascular, and microbiological self-healing.

The Full Study is Readily Available | Download the Sample Pages of this Report@ https://www.precedenceresearch.com/sample/4285

Self-healing Concrete Market Key Insights

- Europe led the self-healing concrete market with the largest market share of 40% in 2023.

- North America is projected to grow at the fastest rate with an exceptional CAGR during the forecast period 2024 to 2033.

- By form, the vascular segment has generated more than 40% of market share in 2023.

- By form, the capsule based segment is expected to grow at the fastest rate in the market during the forecast period.

- By application, the infrastructure segment captured largest market share in 2023.

Europe Self-healing Concrete Market Size and Forecast 2024 to 2033

The Europe self-healing concrete market size is estimated at USD 38.95 billion in 2024 and is expected to expand around USD 463.99 billion by 2033, at a CAGR of 31.67% between 2024 and 2033.

Europe dominated the self-healing market in 2023. Europe dominates the worldwide construction business, which is predicted to increase significantly in the future. Positive private and government debt indicators are driving the sector’s growth. Western European countries, notably Germany, are considerably contributing to the market’s expansion. During the epidemic, government actions and economic assistance enhanced growth in comparison to the United Kingdom and France.

North America is expected to grow rapidly during the forecast period. Demand for long-lasting, environmentally sustainable structures is driving growth in the worldwide construction industry. Vascular-based healing technologies, which rely on self-healing concrete tubes, are expanding the self-healing concrete market.

In emerging countries, the construction of both private and public infrastructure is propelling growth. Government programs such as Make in India promote domestic production by making it simpler to get raw materials. The building sector benefits from these items’ durability and adaptability. The increasing usage of composites, CMCs, and polymer-based materials in construction boosts the industry.

Self-healing Concrete Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 31.51% |

| Self-healing Concrete Market Size in 2023 | USD 74.04 Billion |

| Self-healing Concrete Market Size in 2024 | USD 97.37 Billion |

| Self-healing Concrete Market Size by 2033 | USD 1,145.66 Billion |

| Largest Market | Europe |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Form and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Self-healing Concrete Market Segments Outlook

Form Outlook

The vascular segment dominated the self-healing concrete market in 2023. Vascular healing in concrete follows a biomimetic technique comparable to human cardiovascular and plant vascular tissue systems. It entails establishing networks that transfer liquid healing chemicals to damaged locations, enabling the repair of an endless quantity of material. Dry’s early work involved installing thin glass tubes in concrete, but the use of delicate materials limited its use. Vascular healing provides ongoing provision of different agents for different forms of concrete injury, with varied types of networks formed.

The capsule-based segment is expected to grow at a significant rate during the forecast period. Autonomic self-healing requires additives such as healing-agent-filled microcapsules. Encapsulating a healing agent is a popular method for closing fractures in concrete. The capsule splits the crack, releasing a healing chemical that closes the fracture and stops it from spreading further. This approach lowers the permeability of the concrete matrix and enables partial mechanical recovery. The design cycle for capsule-based self-healing materials consists of capsule encapsulation, mechanical characterization, capsule integration, healing agent triggering and release, and evaluation.

Application Outlook

The infrastructure application segment dominated the self-healing concrete market in 2023. There is a rise in construction. Self-healing concrete is used in various applications, including bridges, highways, residential and commercial structures, tunnels, airports and harbors, dams, and reservoirs. Self-healing concrete is used in various applications, including bridges, highways, residential and commercial structures, tunnels, airports and harbors, dams, and reservoirs. Bridges can repair cracks, acting as built-in maintenance personnel for safety and lifespan. Self-repairing concrete may also help homes and workplaces by allowing small defects to heal themselves and extending the life of the construction. Tunnels, airports, and reservoirs may all benefit from self-healing concrete, which keeps them strong and protected from water and other factors. This revolutionary method of construction focuses not just on building but also on developing smarter and more resilient structures.

The industrial segment is expected to grow at a significant rate during the forecast period. Food processing, Automobiles, plastics, software, and dairy industries all demand high-quality processing units, and businesses cannot afford to have concrete buildings damaged severely. Self-healing concrete is perfect for industrial applications due to its low maintenance needs. This method mitigates corrosion risk while reducing the requirement for crack diagnosis and repair. This provides social, economic, and environmental advantages since it decreases maintenance, enhances longevity, and minimizes interruption, expense, and material consumption.

Read Also: Logistics Market Size to Hit Around USD 21.91 Trillion By 2033

Self-healing Concrete Market Dynamics:

Driver

Enhanced safety

Self-healing concrete makes building projects safer by lowering the chance of structural collapse. It repairs tiny cracks before they jeopardize a building’s structure, assuring long-term stability and safety. Traditional concrete constructions feature fractures that enable water and corrosive chemicals to enter steel rebars, causing corrosion and weakening.

Self-healing concrete not only eliminates the need for steel rebars, but it also actively fixes fissures, reducing the likelihood of corrosive liquids coming into touch. Some self-healing concrete contains fire-resistant elements, such as a multifunctional cementitious composite created by the Stevens Institute of Technology. This novel strategy reduces fire spread and damage, improving safety for residents and nearby properties.

Restraint

High cost

Concrete, the world’s second most often used material, is being studied because of its outstanding compressive strength and low tensile strength, which causes it to shatter easily under stress. However, due to its breaking tendencies, some are trying their hand with self-healing concrete, which may run up to $6,000 per cubic meter. This is due to the higher-level experience and technical understanding necessary to mix the concrete appropriately, which can hinder building procedures.

Additionally, injecting bacteria-infused self-healing concrete might diminish the concrete’s original compressive strength, causing structural difficulties. The expense of this option isn’t the only concern.

Opportunity

Promising future

The self-healing concrete market has the potential for innovation in construction technology, providing a sustainable, environmentally friendly, and long-lasting solution for construction and building projects. As research & development progresses, advances in materials and production techniques are projected to reduce prices and make self-healing concrete more economically practical.

With a growing emphasis on sustainable building techniques and the demand for long-lasting infrastructure, self-healing concrete has the potential to transform the way we build and maintain structures. Despite the availability of knowledge on its benefits, architects, project sponsors, civil engineers, and contractors are hesitant to begin utilizing the material.

Self-healing Concrete Market Top Companies

- Basilisk

- PENETRON

- Kryton

- Xypex Chemical Corporation

- Sika AG

- BASF SE

- Hycrete, Inc.

- Cemex

- Oscrete

- GCP Applied Technologies

- RPM International

Recent Developments:

- In April 2024, the study used metaheuristic approaches such as gray wolf optimization, moth fly optimization, multiverse optimization, particle swarm optimization, and the whale optimization algorithm to enhance the design process and lower expenses in self-healing concrete.

- In February 2024, Researchers observed that some bacteria in chloride-containing concrete could reduce reinforcing steel corrosion via microbially induced CaCO3 precipitation (MICP). This discovery is noteworthy because the quasi-brittle quality of concrete makes it susceptible to hostile ions, which cause steel corrosion. Bacteria-based self-healing concrete has been widely employed for this purpose.

- In November 2023, BioFiber, an innovative self-healing concrete technology that seals fractures using bacterial spores, was created at Drexel University’s College of Engineering. The technique, developed via collaboration between Civil, Mechanical Engineering and Mechanics, Architectural and Environmental Engineering, and Material Science and Engineering, might lessen the need for repairs and maintenance.