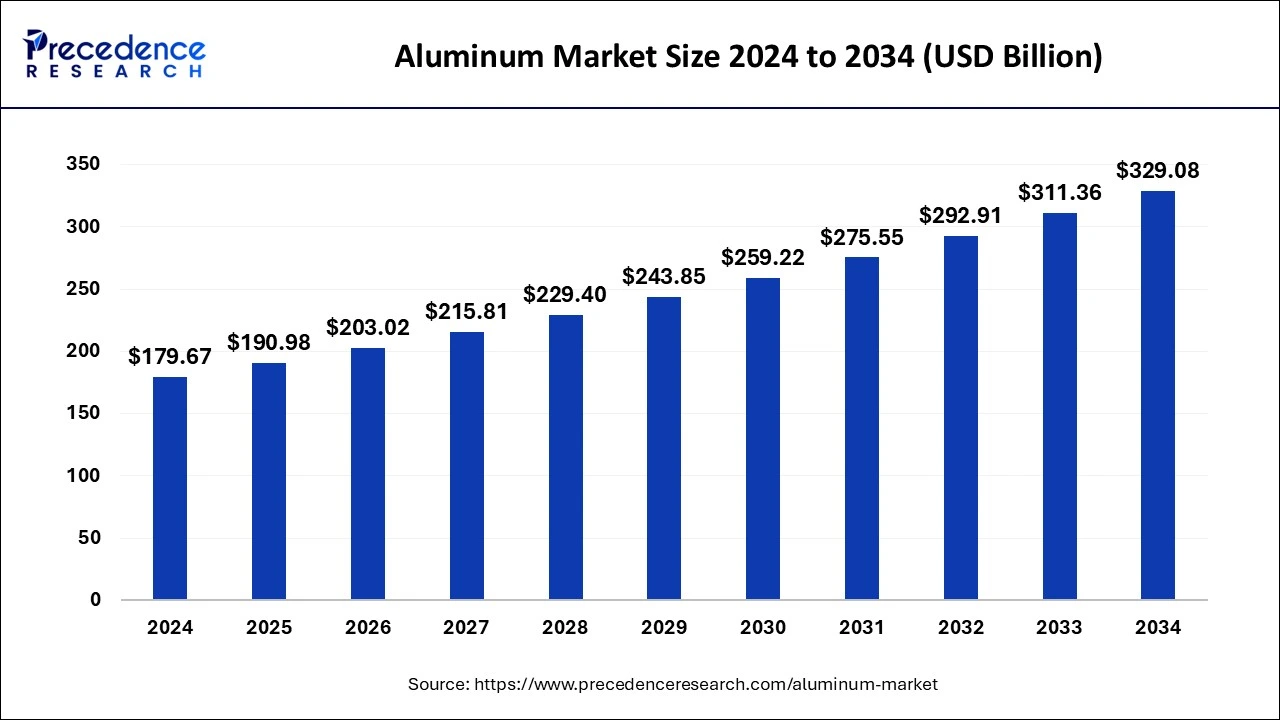

The global aluminum market size was valued at USD 169.02 billion in 2023 and is predicted to hit around USD 311.36 billion by 2033, at a CAGR of 6.3% from 2024 to 2033.

The aluminum market encompasses the global industry involved in the production, processing, distribution, and consumption of aluminum, a versatile and widely used metal. Aluminum is a lightweight, highly functional metal that can be molded, melted, machined, and extruded, among other uses. Because of its low weight, it is simple to transport and assemble, making it appropriate for a wide range of uses. Along with alternatives for surface treatment and a protective coating, aluminum is also resistant to corrosion. It is impermeable, odorless, and a good reflector, in addition to being a great heat and electrical conductor. Utilizing recycled material is economical since it is also entirely recyclable.

Aluminum is utilized in transportation, packaging, food processing, building, energy production, and electrical transmission, among other sectors. Its lightweight nature makes it appropriate for shipbuilding, maritime buildings, and food packaging, while its strength-to-weight ratio and resistance to corrosion make it perfect for automotive components. It is a well-liked option because of its impermeability and resistance to corrosion.

The Full Study is Readily Available | Download the Sample Pages of this Report@ https://www.precedenceresearch.com/sample/2209

Aluminum Market Key Insights

- Asia Pacific dominated the global market with the largest revenue share of 65.14% in 2023.

- By series, the series 1 segment has recorded the biggest revenue share of 20.5% in 2023

- By series, series 7 is expected to grow at a notable CAGR of 7.2% during the forecast period.

- By processing method, the rod & bar segment is expected to grow at a CAGR of 7.1% over the forecast period.

- By end-user insight, the transport segment has captured more than 33% revenue share in 2023.

Asia Pacific Aluminum Market Size and Forecast 2024 to 2033

The Asia Pacific aluminum market size accounted for USD 117.28 billion in 2024 and is expected to be worth around USD 207.05 billion by 2033, growing at a CAGR of 6.5% from 2024 to 2033.

Asia-Pacific dominated the aluminum market in 2023. One of the world’s largest economies, Japan, is a vital market for skyscrapers and other tall structures. Because there will be more money invested in both public and private commercial projects, the construction sector is predicted to rise quickly. Innovations and Internet of Things technology are projected to fuel growth in the automobile sector as well.

- The ‘Make in India’ campaign and other government efforts in India are anticipated to bolster the growth of the aluminum industry. The demand for aluminum is predicted to rise because of these programs and others like the Pradhan Mantri Awas Yojna and Smart Cities, especially in the building and construction industry.

North America is observed to grow at a notable rate in the aluminum market during the forecast period. Governments in North America have implemented supportive policies and regulations that encourage the use of aluminum, such as incentives for recycling and sustainability initiatives. This regulatory environment fosters growth in the aluminum sector. The region benefits from a well-established aluminum supply chain, including mining, refining, smelting, and fabrication industries. This integrated supply chain ensures a reliable and efficient flow of aluminum products to meet growing market demands.

There is a growing demand for aluminum across various industries in North America, including automotive, aerospace, construction, packaging, and consumer goods. This demand is driven by factors such as lightweighting in automotive and aerospace sectors, sustainable packaging solutions, and the versatility of aluminum in construction and consumer products.

Aluminum Market Scope

| Report Coverage | Details |

| Market Size in 2023 | USD 169.02 Billion |

| Market Size in 2024 | USD 179.67 Billion |

| Market Size by 2033 | USD 311.36 Billion |

| Growth Rate from 2024 to 2033 | CAGR of 6.3% |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Series, Type, Processing Method, and End-Use Industry |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Aluminum Market Segments Outlook

Series Outlook

The series 1 segment dominated the worldwide aluminum market. With an ultimate tensile strength ranging from 10 to 27 ksi and a 99.99% pure aluminum composition, the pure aluminum series is normally weldable but cannot be heat-treated because of its susceptibility to high temperatures. It is perfect for chemical tanks and pipelines due to its exceptional electrical and thermal conductivity and corrosion resistance.

Processing Method Outlook

The extrusion segment is anticipated to increase at a significant rate during the forecast period. For molding, aluminum extrusion provides twelve key benefits. It works well for both cold extrusion, which happens at lower temperatures, and hot extrusion, which happens at higher temperatures.

The procedure uses less energy, needs less pressure, and might work best at a moderate temperature. It may be produced in a long time since it can take on a range of sizes and forms. It can be used with other metalworking techniques such as drilling, cutting, bending, stamping, and pressing. Machines for milling and turning with digital controls enable large-scale form modifications with excellent dimensional precision.

End-Use Industry Outlook

The transport segment dominated the aluminum market in 2023. Aluminum is a thin material that may be made lighter by up to 50% without losing strength. Additionally, it is impact-resistant, absorbing twice as much energy in a collision. Because lighter automobiles are more fuel-efficient and may lower the weight of important systems like engines, gearboxes, and suspensions, lighter cars are the main market for automotive manufacturers. Because of its strength and less weight, aluminum can stop more rapidly and has fewer joints, which increases safety in public transportation. Furthermore, the corrosion resistance of aluminum increases its longevity and vehicle life cycle.

Read Also: U.S. Payment Integrity Market Size to Hit USD 10.27 Billion by 2033

Aluminum Market Dynamics

Driver

Natural anti-corrosion property

The natural anti-corrosion property of aluminum is a key driving factor for the growth of the aluminum market. Solutions for the aluminum industry are essential for sectors subjected to high temperatures, dampness, and abrasives. They aid in preventing corrosion brought on by moisture, sea spray, and salty air. Without further processes like painting, anodizing, or powder coating, aluminum oxide, which is produced when exposed to oxygen, offers a naturally occurring thin layer of protection. This makes the product longer-lasting, less maintenance-intensive, and more aesthetically beautiful. Unlike steel, which becomes brittle in low temperatures, aluminum gets stronger in cold temperatures, making it perfect for winter or polar regions.

Restraint

Component complexity

Component complexity is a major concern in the aluminum market. The major engine component, the cylinder block, produces power and contains a variety of moving elements. Aluminum alloys, once built of cast iron alloys, are now often used in passenger automobiles to reduce weight. Roughening and finishing are two difficult, time-consuming steps in the manufacturing of cylinder blocks. The aluminum cylinder head also contains fuel injectors, spark plugs, and valves and transports fuel and air to the combustion chamber. Both parts must be expertly machined, so there must be more setup and coolant to dissipate heat.

Opportunity

Integrated purification process

Novel advanced purification process has a great opportunity in the aluminum market. Large aluminum continuous casting and rolling factories frequently utilize integrated purification, a method that includes adsorption and non-adsorption purification. Melt purity and product quality are greatly enhanced. Nevertheless, the cost and complexity of the existing composite purification techniques may outweigh the benefits of lowering hydrogen concentration and enhancing alloy characteristics. Most integrated purification systems are still in the experimental phase, and further research is required to guarantee their viability and dependability. Through purifying procedures, researchers have improved the characteristics of aluminum alloys, yet most procedures still have flaws. Further investigation is required to create more effective procedures to improve performance and raise application value.

Aluminum Market Companies

- Alcoa Corporation (U.S.)

- Aluminum Corporation of China Limited (CHALCO) (China)

- Century Aluminum Company (U.S.)

- China Hongqiao Group Limited

- China power investment corp. (cpi)

- China zhongwang holdings limited (china)

- Dubai Aluminum Company Limited (U.A.E)

- East Hope Group (China)

- Emirates Global Aluminium (UAE)

- H.P. (Australia)

- Hindalco Industries Ltd. (India)

- Kaiser Aluminium

- Norsk Hydro A.S.A. (Norway)

- Novelis (U.S.)

- Rio Tinto Ltd.

- United Company RUSAL Plc, (Russia)

- Vedanta Aluminium Limited (India)

- Xinfa group co. Ltd.

Recent Developments:

- November 2021, Following the publication of the findings of scientific testing of their Enhanced Modified Aluminium Ion (Ea2I) battery technology, Saturnose disclosed intentions to manufacture a solid-state, recharged aluminum battery. It is anticipated to be the first advertisement for aluminum-ion solid-state batteries when it debuts the following year, opening the door for a protracted, gradual transition away from the hazardous rechargeable battery technology.

- Rio Tinto spent million at its AP60 smelter in the Saguenay-Lac-Saint-Jean region of Quebec in November 2021 to increase the amount of low-carbon aluminum it produces in Canada by adding 16 new smelting cells. The investment will increase annual primary aluminum smelter production by nearly 45 %, or 26,500 mt, to 86,500 mt. Rio Tinto predicts that during the following ten years, the worldwide aluminum market would rise at an annual compound growth rate of 3.3%, driven by strong demand from the energy revolution and decarbonization.

- Dec 2020, The Centre for Biological Technology at the University of Queensland (CBT-QUT) has successfully wet-etched nanomaterials with a thickness of 21–25 nm into an aluminum 6063 alloy plane as part of the latest developments on COVID’s external inactive. This demonstrated that COVID-19 remained dormant for six hours on robust antiviral nanostructured surfaces. Cicada’s Antimicrobial Nanoparticles Solutions for COVID-Free Surface has shown remarkable potential in maintaining COVID-19-free public spaces and is a great starting point for future studies should the next epidemic occur.

- Dec 2020 As the Indian market recovers from the coronavirus outbreak, Hindalco Industries Limited has reenergized a million-dollar strategy to produce additional aluminum goods with value added. By setting up a 34,000-ton extruded aluminum project in Silvassa’s west Indian city, the company will launch its ongoing downward investing strategy. Production is anticipated to begin in two years.

- Aleris Corporation, a major supplier of rolled aluminum goods on a global scale, was purchased by Novelis, a division of Hindalco Industries Limited in April 2020. The combination of complementary resources, including casting, rolling, recycling, and finishing technologies, has improved Novelis’ position in the market. This action will assist the business in satisfying the significant consumer demands.

- Krasnoyarsk Aluminum Refinery (KrAZ) has finished making the switch to EcoSoderberg technologies, according to UC RUSAL’s announcement from July 2020. The refurbishment cost the corporation USD 74 million. The EcoSoderberg procedure modification required a minimum of 1954 reducing cells. The Technology and Engineering Center at UC RUSAL created the procedure.

Web: https://www.precedenceresearch.com/