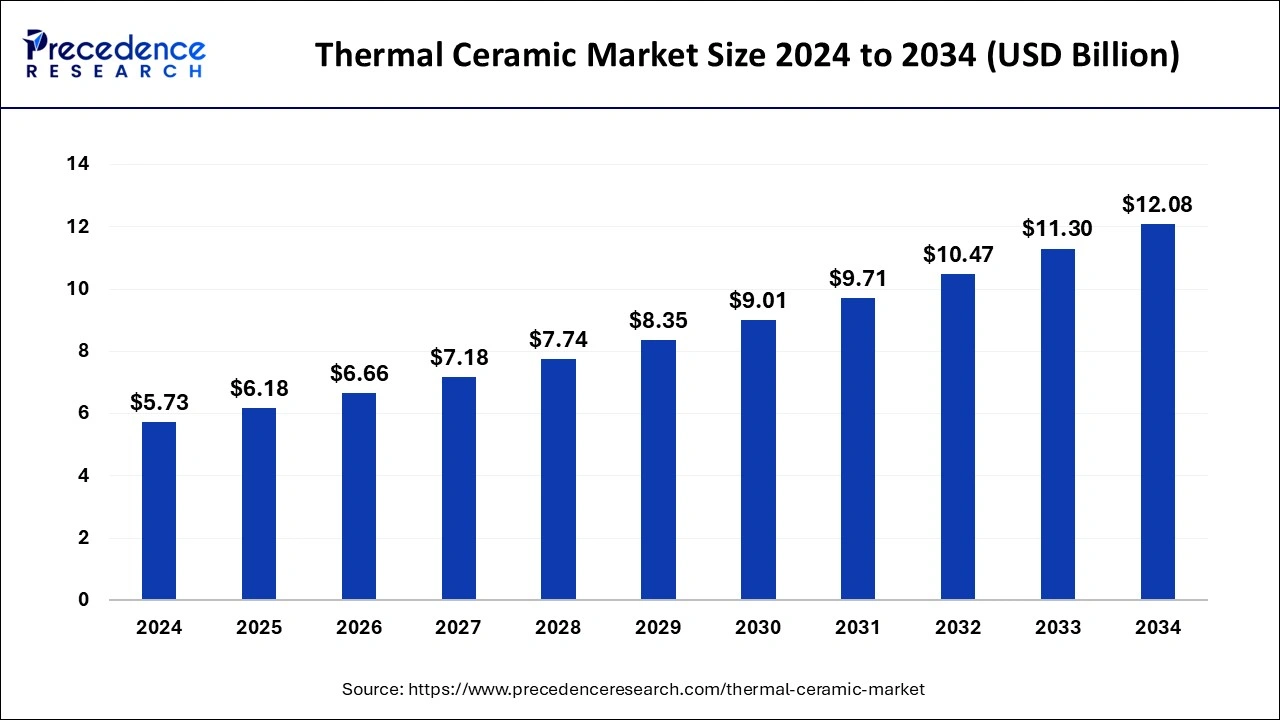

The global thermal ceramic market size reached USD 5.31 billion in 2023 and is predicted to cross around USD 11.30 billion by 2033, growing at a CAGR of 7.84% from 2024 to 2033.

The thermal ceramic market refers to the industry involved in the production, distribution, and application of materials designed to withstand high temperatures and possess thermal insulating properties. Ceramics are mixtures of metallic and nonmetallic materials, commonly crystalline oxide, nitride, or carbide. They have distinct physical features that are enhanced through thermal treatment. Ceramics’ varied properties due to bonding variations make them useful in a variety of technical applications.

The Full Study is Readily Available | Download the Sample Pages of this Report@ https://www.precedenceresearch.com/sample/4303

Polycrystalline ceramics cannot be processed using conventional methods; most ceramic items are manufactured from ceramic powders. Glass objects can be formed by pressing, blowing, drawing, or fiber-forming. Bonding ceramics to ceramics or ceramics to metals has been a worry since 2010, but the fundamental problem is making close contact between materials. Today, technologies for self-bonding ceramics or ceramics to metal have been created. Ceramics have several applications in the electronics and production sectors.

Thermal Ceramic Market Key Insights

- Asia Pacific dominated the thermal ceramic market in 2023.

- Europe is expected to witness the quickest growth during the forecast period.

- By application, the industrial segment led the market in 2023.

- By application, the petrochemical & chemical is expected to grow with the highest CAGR during the forecast period.

Thermal Ceramic Market Segments Outlook

Application Outlook

The industrial segment dominated the thermal ceramic market in 2023. Ceramics are used in metallurgical operations, glass manufacture, and other sectors because of their strength, durability, and non-corrosive qualities. Advanced ceramics are utilized in steelmaking and quarrying because they last longer than traditional metal gears. Abrasives are required for sophisticated machinery and smooth finishes in many industries, including steel, Construction, stone processing, metal processing, vehicle manufacturing, clean-tech, space, glass, wood processing, shipbuilding, machine-building, and military.

Refractories offer mechanical strength, corrosion resistance, and thermal insulation in high-temperature industrial operations. Porcelain enamel, also referred to as vitreous enamel, is a high-tech coating with ceramic properties that is applied to metal objects such as hot water tanks, gadgets, pans, pots, and sanitary ware.

The petrochemical & chemical segment is expected to witness the fastest growth in the thermal ceramic market. Ceramic matrix composites are used extensively in the chemical and petrochemical industries for pipe fabrication, pumps, gasification systems, thermal barrier coatings, thermal insulating fabrics, and electrical insulators for components of machinery and sensors.

Regional Outlook

Asia Pacific dominated the thermal ceramic market in 2023. Market growth is due to a wide range of applications in different sectors. Thermal ceramics are used in various applications, including fire doors, furnace insulation, resistance to heat containers, and heating pipes. They are also utilized in the glass, ceramic, electrolytic, and power production industries. The desire for metal processing in equipment and machinery manufacture is also rising. Thermal ceramics are also employed in power plants, automobiles, and electronic systems that protect against fire. Thermal ceramics are becoming more common in the cement, glass, ceramic, and transportation industries as countries build their infrastructure.

Europe is estimated to witness the fastest growth during the forecast period. Thermal ceramics are employed in a variety of industries, including energy, gas and oil, and solar energy generation. They are utilized in solar panels and photovoltaics to generate electricity, which promotes thermal ceramic market growth. Europe’s growing construction activity fuels the demand for thermal ceramics. The extensive usage of ceramic heaters, process heaters, and high-temperature purification products is likely to drive the expansion.

Thermal Ceramic Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 7.84% |

| Thermal Ceramic Market Size in 2023 | USD 5.31 Billion |

| Thermal Ceramic Market Size in 2024 | USD 5.73 Billion |

| Thermal Ceramic Market Size by 2033 | USD 11.30 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Thermal Ceramic Market Top Companies

- Coors Tek

- Rath

- 3M

- RHI Magnesita

- Saint-Gobain

- Ceram Tech Gmbh

- Ibiden

- Unifrax I LLC

Recent Developments

- In April 2024, a ceramic-based temperature sensor was created for real-time monitoring of harsh ambient temperatures, such as high temperatures and severe oxidation/corrosion conditions. The sensor is critical for determining gas combustion efficiency, monitoring engine operation, and detecting faults in aircraft engines.

- In February 2024, Krahn Ceramics, a Hamburg-based company, will demonstrate at the International Advanced Ceramics Exhibition China in Shanghai from March 6 to 8, 2024. The company will show off its services at stand E1609, hoping to create contacts and exchange ideas about developments and trends in China, a prospective market for the company.

- In January 2024, Chinese scientists created a porous ceramic that is ultra-strong at high temperatures and highly thermally insulating, which is critical for the shell of hypersonic aircraft. The researchers, led by Chu Yanhui of the South China University of Technology, created porous high-entropy diboride ceramics with load-carrying capabilities, excellent thermal insulation, and exceptional thermal stability up to 2,000 degrees Celsius.

Thermal Ceramic Market Dynamics

Drivers

Application of thermal ceramic in aerospace

The usage of thermal ceramics in aerospace is a major driver for the thermal ceramic market. Ceramic materials are suited for aircraft applications because they can maintain the integrity of structures at high temperatures, have great scratch and corrosion resistance, and are lightweight. They find applications in current aviation engines, piezoelectric ceramics, and heat-resistant tiles for pressure sensors and rocket engine exhaust monitoring.

A recent study investigated the use of oxide-oxide ceramic matrix composites (OCMCs) in rocket engines, namely in rocket thrust chambers. The study discovered that simple OCMC geometries performed well in hot firings, indicating their potential usage as lightweight parts in rocket engines. Ceramics have higher heat resistance than standard metal alloys, permitting engines to run warmer and more effectively.

Read Also: Asset Management Market Size to Cross USD 10,478.93 Bn By 2033

Thermal ceramic coatings as energy-saving alternatives for high-temperature processes

The continuing energy crisis presents tremendous opportunities to reduce energy use in high-temperature operations. Thermal coatings provide an inexpensive and technological alternative for customizing material surface optical characteristics.

However, there is a dearth of knowledge of the relationship between solid-state physical matter, thermal radiation heat transfer, and material science technologies. The study seeks to link these regions to give suggestions for proper thermal ceramic coating application, leading to maximum energy consumption reduction.

Restraint

Difficulties during processing

Deformation, cracking, and foaming are three major issues that can affect the ceramic production process and restrict the thermal ceramic market’s growth. Deformation is a typical problem that causes irregular cylinder diameters and geometrical forms due to poor kiln-drying techniques and excessive fire temperatures.

Cracks form when temperatures rise too quickly, causing uneven shrinkage within and outside the product. Foaming occurs due to the insufficient oxidation of breakdown in porcelain tires and glazes, as well as the presence of sulphate and organic contaminants in billet glazes. These concerns can cause many defects and must be addressed.

Opportunity

Usage in the electronic sector

The electronic field concentrates on the micro miniaturization of electronic gadgets, with ceramic engineers exploring novel materials and processing methods to convert nonfunctional packaging pieces into functional components. This will result in magnetic levitation vehicles, optoelectronic integrated circuits, inexpensive electricity, and enhanced MRI. High-temperature superconductors will be used in micro-applications such as sensors and memory storage devices, enabling enhanced magnetic resonance imaging.

The automotive sector is also investigating ceramics for enhanced sensors and engine components that are light in weight, strong, and can withstand high temperatures. Ceramics are also employed in ceramic fuel cells, batteries, solar cells, and energy transfer via fiber optics. Ceramics are also employed in bionic/andromic applications, such as microscopic hearing and vision devices and skeletal systems. As ceramic materials increase in strength, compatibility, nonreactivity, lifespan, porosity, and affordability, they will be used more frequently.