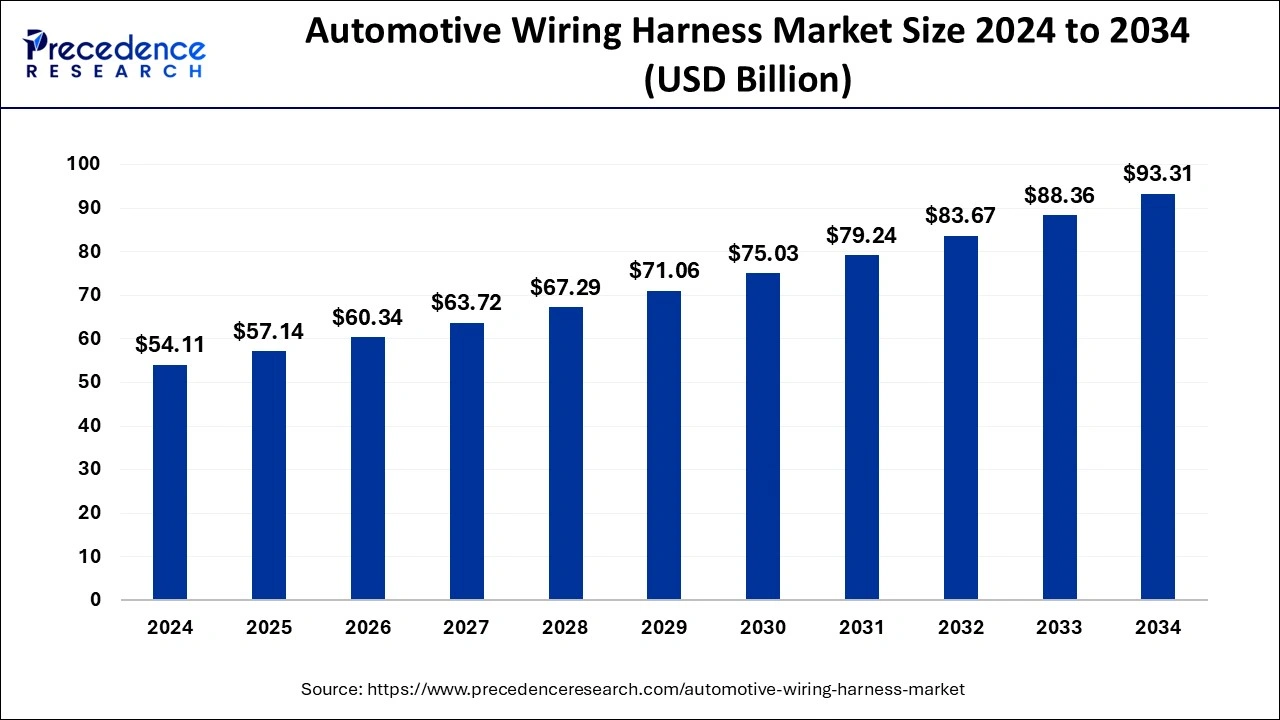

The Automotive Wiring Harness Market is valued at USD 54.11 billion in 2024 and is projected to soar to USD 93.31 billion by 2034, growing at a dynamic CAGR of 5.60% during the forecast period.

Critical Observations

- In 2024, the Asia Pacific region led the global market with the largest share of 48%.

- By material, copper dominated with a substantial market share of 65%.

- In terms of propulsion, ICE vehicles captured the highest market share of 82%.

- Passenger cars generated the largest share by vehicle type, accounting for 58% of the market.

- The low voltage segment held the dominant share of 85% in terms of voltage.

The automotive wiring harness market is witnessing substantial growth, fueled by the rising demand for advanced electrical systems in vehicles. These harnesses play a crucial role in connecting key components, such as automotive lighting, infotainment, and active safety systems. As electric and autonomous vehicles become more prevalent, the need for sophisticated wiring solutions is increasing. With ongoing technological advancements and a surge in automotive production, the market is projected to reach USD 93.31 billion by 2034.

Sample Link: https://www.precedenceresearch.com/sample/1008

Market Scope

| Report Highlights | Details |

| Market Size in 2024 | USD 54.11 Billion |

| Market Size in 2025 | USD 57.14 Billion |

| Market Size by 2034 | USD 93.31 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 5.60% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Material, Propulsion, Transmission, Vehicle, Sales Channel, Geography |

Core Factors

Automotive wiring harness is driven by the fast pace of adoption of electric and autonomous vehicles, which require more complex wiring to support their high electrical systems. The growing expectation of consumers in terms of infotainment, safety, and comfort inside a vehicle is pushing the need for more complex wiring designs. Lightweight and energy-efficient vehicles are also encouraging innovation in harness technology. Other government mandates towards vehicle safety, and emission, are also moving the development process and implementation for advanced automotive wiring systems.

Potentials

- Electric Vehicle Extension: With the increased adoption of electric vehicles, specialized wiring harnesses designed to support electric drivetrains, battery management systems, and charging infrastructure see substantial demand.

- Advancements in Autonomous Vehicles: Self-driving vehicles will bring new opportunities for sophisticated wiring solutions to be able to support complex sensors, cameras, and communication networks.

- Focus on Lightweight Solutions: In the context of fuel efficiency and weight reduction for better automotive, manufacturers require more lightweight and high-performance wiring harnesses.

- Increasing vehicles: Increacing vehicles road are promoting growth in aftermarket. More replacement and repair of the wiring harness have to be required in this particular sector of aftermarket.

- The coming of smart wiring harness with sensing capabilities and Internet of Things integration is offering fascinating opportunities in this market.

- Sustainability Initiatives: Increased environmental awareness and regulatory compliance are driving demand for eco-friendly materials in wiring harness production, leading manufacturers to find sustainable solutions.

Obstacles

- Complexity and Customization: The modern high-tech automobiles, especially electric and autonomous types, involve a requirement for much customized wiring harnesses, making the design and manufacturing tedious and costly processes.

- Rising Raw Material Costs: Salient fluctuations in the prices of copper, aluminum, and plastics form essential materials that directly influence production costs and the profit margins.

- Quality Control and Reliability: Wiring harness quality and durability need to be absolutely sound because faults lead to critical safety issues or costly recalls and require strict quality control and testing procedures.

- Compact Vehicle Space Issues: With smaller and more high-tech vehicles on the road today, the complexities of wiring harnesses pose a substantial challenge in developing such harnesses for installation into space-constrained compact vehicles while performing their intended role safely.

- Global Supply Chain Challenges: Delays in sourcing materials and components, disruptions in the global supply chain may lead to increased production times and higher lead times for manufacturers.

- Environmental Compliance: Increased regulatory restrictions on environmental degradation and increasing emphasis on green material development forces the manufacturers to come up with environmentally friendly wiring harnesses that remain economical.

Regional Insights

In 2024, Asia Pacific dominated the market for the automotive wiring harness globally, followed by 48% of global market share because of the upsurge in automobile production as well as widespread usage of latest technologies. In this, copper material accounted for a 65% share owing to its maximum utilization in the wiring solutions with superior conductivity and reliability. Internal Combustion Engine (ICE) remained as the primary driver with an 82% share in the market. In this segment, Passenger Car has seen significant demand holding a share of 58%. The other main share came in Low-Voltage Wiring Harness that captured the major 85% of the market.

Don’t Miss Out: Concentrated Solar Power Market

Industry Leaders

- Sumitomo Electric Industries, Ltd.

- Delphi Automotive LLP

- Furukawa Electric Co. Ltd

- Lear Corporation

- THB Group

- Yura Corporation

- Leoni Ag

Recent Insights

As of 2024, the Asia Pacific region captures the largest share of the automotive wiring harness market globally at 48%. This can be attributed to the growing automotive production and developing adoption of advanced technologies within this region. Copper remained leading, with 65% share, as a consequence of its excellent conductivity and reliability in wiring solutions. ICE vehicles took the largest share of propulsion systems with an 82% market share, and passenger cars were one of the most dominating forces in terms of market share contributions at 58%. Low-voltage wiring harnesses also topped the list of most demanded, claiming a market share of 85%.

Market Segmentation

By Type

- Engine Harness

- Dashboard/ Cabin Harness

- Battery Wiring Harness

- Chassis Wiring Harness

- Body & Lighting Harness

- HVAC Wiring Harness

- Seat Wiring Harness

- Door Wiring Harness

- Sunroof Wiring Harness

By Material

- Metallic

- Aluminum

- Copper

- Other Metals

- Optical Fiber

- Plastic Optical Fiber

- Glass Optical Fiber

By Propulsion

- IC Engine Vehicle

- Electric Vehicle

By Transmission

- Electric Wiring

- Data Transmission

- <150 Mbps

- 150 Mbps to 1 Gbp

- >1 Gbps

By Vehicle

- Commercial Vehicle

- Passenger Vehicle

By Voltage

- Low Voltage

- High Voltage

By Sales Channel

- OEM

- Aftermarket

Ready for more? Dive into the full experience on our website!