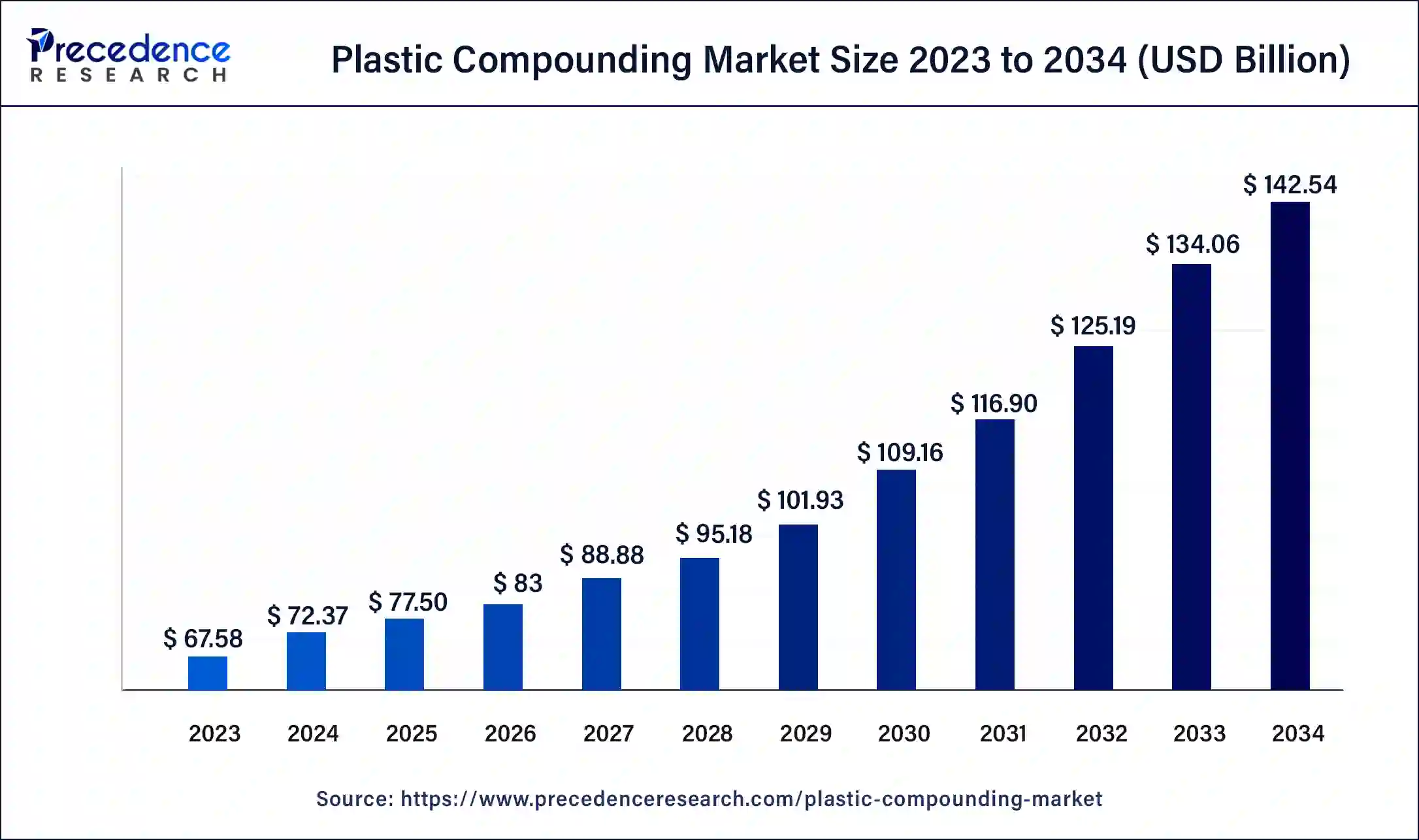

The plastic compounding market is forecast to grow from USD 72.37 Bn in 2024 to USD 142.54 Bn by 2034 at a CAGR of 7%.

Plastic Compounding Market Critical Observations

- Asia Pacific led the global market in 2023, securing the highest share of 46%.

- The automotive application contributed to more than 26% of the total revenue in 2023.

- Polypropylene (PP) emerged as the dominant product with a 33% market share in 2023.

The plastic compounding market is fueled by the rising need for customized materials in sectors such as automotive, construction, and consumer electronics. Key factors driving growth include the demand for lightweight, high-strength materials and the continuous development of advanced polymer compounds. Innovations in polymer blends are enhancing product performance and expanding their usage in various industries. Additionally, there is a notable shift toward sustainable plastic solutions, driven by stricter environmental regulations and consumer preference for eco-friendly products.

Sample Link: https://www.precedenceresearch.com/sample/1015

Market Scope

| Report Highlights | Details |

| Market Size in 2023 | USD 67.58 Billion |

| Market Size in 2024 | USD 72.37 Billion |

| Market Size by 2034 | USD 142.54 Billion |

| Growth Rate from 2024 to 2034 | CAGR of 7% |

| Largest Market | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Product, Application, Region |

Core Factors

Potentials

- Increasing infrastructure projects in developing nations drive demand for plastic compounds in construction.

- Continuous innovations in catalyst technology boost plastic resin yield, benefiting industry players.

- A shift toward environmentally friendly products opens new opportunities for bio-based polymers.

- The automotive industry’s push for lightweight, energy-efficient components boosts plastic compounding growth.

- The growing packaging industry supports the rise of plastic compounding for versatile packaging solutions.

Obstacles

- The growing popularity of biodegradable, bio-based polymers could disrupt the demand for traditional plastics.

- Regulatory changes pushing for sustainability may limit the use of petrochemical-based plastics.

- The shift to bio-based alternatives in medical and agricultural applications poses a competitive challenge.

- Environmental concerns and plastic waste management issues create pressure on the industry to innovate.

- Price volatility of raw materials, especially for plastic resins, could impact the market’s growth potential.

Regional Insights

The Asia Pacific plastic compounding market, with China and India at the forefront, is expanding rapidly due to the increasing demand for biodegradable polymers, robust infrastructure development, and a surge in production within the automotive and electronics industries. The region accounted for 46% of the global market share in 2023, propelled by rapid industrialization, rising disposable incomes, and heightened consumer awareness of environmental sustainability. Additionally, the growing adoption of eco-friendly materials and the ongoing expansion of manufacturing facilities in countries like India, China, and South Korea are set to further strengthen the market’s position in the coming years.

Don’t Miss Out: Aquafeed Additives Market

Industry Leaders

- The Dow Chemical Company

- LyondellBasell Industries N.V.

- SABIC

- Covestro (Bayer Material Science)

Recent Insights

The plastic compounding sector has seen noteworthy advancements. Geon Performance Solutions has bolstered its presence in the medical sector by acquiring Foster Corp., a leading producer of medical-grade plastics. In an exciting move, a Cornish startup, Fishy Filaments, is transforming discarded fishing nets into durable nylon for 3D printing applications, catching the attention of eco-conscious companies like Ford and Mercedes-Benz.

Borealis AG has strengthened its recycling capabilities with the purchase of Integra Plastics AD, significantly boosting its polyolefin recyclate production. Meanwhile, European plastic manufacturers are grappling with a decline in production, falling by 8.3% in 2023, due to a global material surplus, escalating energy costs, and stringent regulations. These trends underscore the industry’s drive to innovate and adapt amidst market and environmental pressures.

Market Segmentation

By Application

- Electronics & Electrical

- Automotive

- Packaging

- Building & Construction

- Industrial Machinery

- Optical Media

- Consumer Goods

- Medical Devices

- Others

By Product

- Thermoplastic Polyolefins (TPO)

- Poly Vinyl Chloride (PVC)

- Polypropylene (PP)

- Polyethylene

- Thermoplastic Vulcanizates (TPV)

- Polystyrene

- Polybutylene Terephthalate (PBT)

- Polycarbonate

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene (PET)

- Polyamide

- PA 6

- PA 66

- PA 46

- Others

By Source

- Fossil-based

- Bio-based

- Recycled