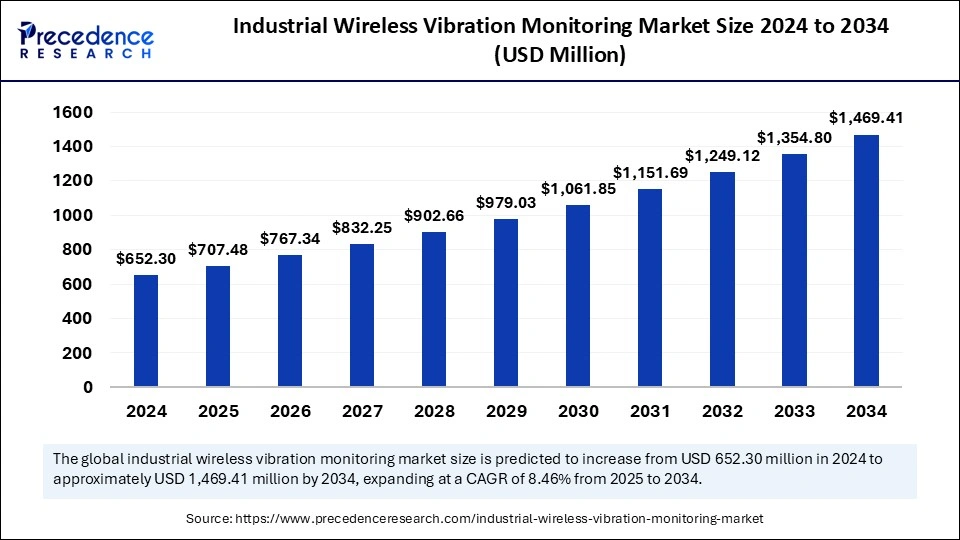

The global industrial wireless vibration monitoring market is expected to grow from USD 652.30 million in 2024 to approximately USD 1,469.41 million by 2034, registering a CAGR of 8.46%.

Industrial Wireless Vibration Monitoring Industry Critical Observations

- North America dominated the market by holding 36% of market share in 2024.

- Europe is expected to witness the fastest growth in the coming years.

- By type, the wireless sensors segment held the biggest market share of 37% in 2024.

- By type, the data acquisition systems segment is projected to grow at the fastest rate during the forecast period.

- By application, the condition monitoring segment contributed the highest market share of 42% in 2024.

- By application, the predictive maintenance segment is anticipated to grow rapidly during the projection period.

The industrial wireless vibration monitoring market is experiencing significant growth, driven by the increasing need for predictive maintenance and real-time asset monitoring in industries such as manufacturing, oil & gas, power generation, and automotive. Wireless vibration monitoring systems help detect equipment faults early, reducing unplanned downtime and maintenance costs. These systems use IoT-enabled sensors, cloud-based analytics, and AI-driven insights to enhance operational efficiency and asset reliability. With the growing adoption of Industry 4.0 and smart factory initiatives, the demand for wireless vibration monitoring solutions is expected to rise significantly in the coming years.

Sample Link: https://www.precedenceresearch.com/sample/5692

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 1,469.41 Million |

| Market Size in 2025 | USD 707.48 Million |

| Market Size in 2024 | USD 652.30 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 8.46% |

| Dominating Region | North America |

| Fastest Growing Region | Europe |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Core Factors

Several factors are fueling the expansion of the industrial wireless vibration monitoring market

- Rising Demand for Predictive Maintenance – Industries are shifting from reactive to predictive maintenance strategies to reduce operational disruptions and enhance equipment longevity.

- Growth of Industry 4.0 & Smart Manufacturing – The integration of IoT, AI, and cloud computing in industrial settings is accelerating the adoption of wireless monitoring solutions.

- Cost-Effectiveness & Efficiency of Wireless Solutions – Wireless sensors eliminate the need for complex wiring, reducing installation and maintenance costs while enabling remote monitoring.

- Increasing Focus on Worker Safety – By enabling early fault detection, wireless vibration monitoring enhances workplace safety by preventing catastrophic machinery failures.

- Expansion of Industrial Automation – With increasing automation across industries, real-time data monitoring through wireless sensors has become essential for optimizing operations.

Potentials

The industrial wireless vibration monitoring market offers several growth opportunities

- Adoption in Emerging Markets – Developing economies are investing in industrial automation and predictive maintenance, creating new market opportunities.

- Integration with AI & Machine Learning – AI-powered analytics can enhance vibration data interpretation, leading to more accurate fault detection and predictive insights.

- Advancements in Wireless Connectivity – The rollout of 5G and improvements in wireless communication technologies will enhance the reliability and efficiency of vibration monitoring systems.

- Growing Demand in Renewable Energy Sector – Wind and solar power plants require real-time equipment monitoring to improve operational efficiency and minimize downtime.

- Expansion of Cloud-Based Monitoring Solutions – The rise of cloud-based predictive maintenance platforms enables remote monitoring and data-driven decision-making.

Obstacles

Despite the market’s growth potential, several challenges need to be addressed

- High Initial Investment & Integration Costs – While wireless systems reduce long-term costs, initial setup and integration expenses can be high, limiting adoption.

- Data Security & Privacy Concerns – Wireless networks and cloud-based monitoring systems are vulnerable to cybersecurity threats, requiring robust security measures.

- Limited Awareness & Technical Expertise – Some industries, especially in developing regions, lack awareness and technical expertise for adopting wireless monitoring solutions.

- Reliability & Battery Life of Wireless Sensors – The performance of wireless sensors can be affected by battery life and environmental conditions, requiring frequent maintenance and upgrades.

- Regulatory & Compliance Challenges – Industries must comply with stringent regulations regarding wireless communication and industrial safety standards, which can slow adoption.

Regional Insights

- North America – Leading the market due to strong adoption of predictive maintenance solutions, Industry 4.0 initiatives, and the presence of key players in the U.S. and Canada.

- Europe – The region is witnessing significant growth driven by industrial automation, government regulations promoting workplace safety, and advancements in wireless technologies.

- Asia-Pacific – The fastest-growing region, with increasing adoption in China, India, and Japan due to rapid industrialization, expansion of manufacturing facilities, and investment in smart factories.

- Latin America & Middle East & Africa – These regions are gradually adopting wireless vibration monitoring solutions, driven by increasing investments in oil & gas, power generation, and heavy industries.

Don’t Miss Out: Video Streaming Market

Industry Leaders

- GE Vernova

- Honeywell

- Siemens

- Fluke Corporation

- SKF Group

Recent Insights

- Technological Innovations – Companies are launching next-generation wireless vibration sensors with AI-powered analytics for enhanced predictive maintenance.

- Strategic Partnerships – Key players are collaborating with industrial automation firms to expand their wireless monitoring solutions.

- Regulatory Advancements – Governments and industry bodies are introducing new guidelines for industrial asset monitoring to improve workplace safety and operational efficiency.

- Increased Investments in IoT-Based Solutions – The integration of IoT and cloud computing in industrial monitoring is gaining traction, with companies investing in data-driven asset management solutions.

The industrial wireless vibration monitoring market is set for significant growth, driven by advancements in predictive maintenance technologies and increasing automation across industries. As businesses continue to prioritize operational efficiency, safety, and cost reduction, the demand for wireless vibration monitoring systems is expected to surge in the coming years.

Market Segmentation

By Type

- Wireless Sensors

- Wireless Controllers

- Vibration Transmitters

- Data Acquisition Systems

- Vibration Analysis Software

By Application

- Condition Monitoring

- Asset Management

- Predictive Maintenance

- Machine Health

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa (MEA)