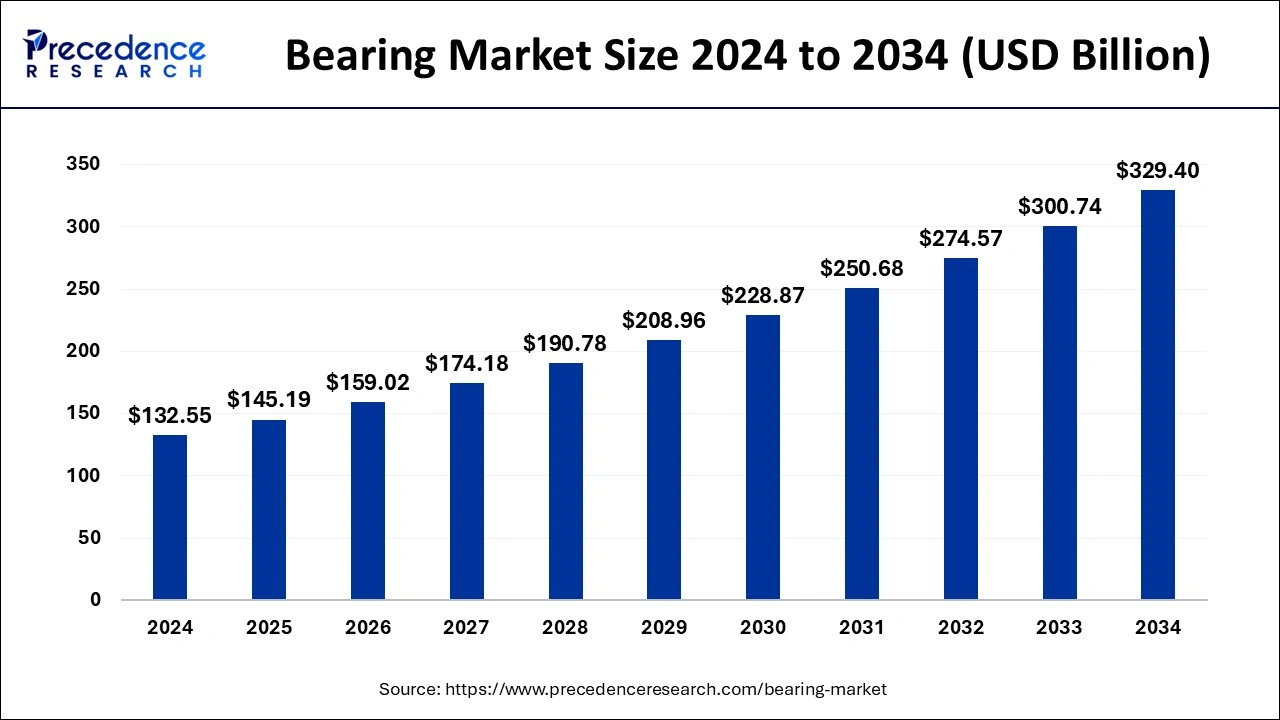

The global bearing market was valued at USD 132.55B in 2024, set to grow to USD 329.40B by 2034 with a CAGR of 9.53%.

Bearing Market Critical Observations

- Asia Pacific led the global market in 2024 with a 41% share.

- Roller bearings held the largest product share in 2024.

- The automotive sector dominated applications in 2024.

- Railway and aerospace applications are expected to see significant growth during the forecast period.

The global bearing market is experiencing significant growth, valued at USD 132.55 billion in 2024 and projected to reach USD 329.40 billion by 2034, with a CAGR of 9.53%. Asia Pacific leads the market with a dominant 41% share, driven by rapid industrialization and demand from the automotive and machinery sectors. Roller bearings are the most widely used product, while the automotive segment captures the largest application share. Meanwhile, railway and aerospace applications are expected to grow rapidly during the forecast period, fueled by advancements in transportation technologies.

Sample Link: https://www.precedenceresearch.com/sample/1020

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 329.40 Billion |

| Market Size in 2025 | USD 145.19 Billion |

| Market Size in 2024 | USD 132.55 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 9.53% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Type, Material, Distribution Channels, Size, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Core Factors

Rising incomes and population growth have spiked demand for food and beverages, driving investments in food processing and packaging equipment. Bearings, especially food-grade stainless steel ball bearings, play a vital role in ensuring efficient, safe operations in food and beverage machinery. Similarly, the medical sector’s reliance on miniature bearings for precision tools and devices boosts demand. Bearings must meet stringent standards like low noise, friction, and maintenance, coupled with high reliability and resilience, fueling market growth.

Potentials

- Rising demand for bearings in wind turbines due to the growth of renewable energy sectors.

- Customization of bearings for specific wind turbine components like propellers, shafts, and generators.

- Advancements in asymmetric spherical roller bearings to enhance power transmission efficiency.

- Development of bearings that minimize friction, thermal expansion, and heat energy loss in turbines.

- Continuous innovation in ball bearings to improve turbine efficiency and renewable energy applications.

Obstacles

- High customization requirements for bearings in wind turbine components increase production complexity.

- Bearings in turbines face significant wear and tear due to continuous operation and heavy loads.

- Thermal expansion and energy loss in bearings can reduce turbine efficiency.

- Development of advanced bearings, such as asymmetric spherical roller bearings, involves high R&D costs.

- Ensuring reliability and durability in extreme environmental conditions is a significant challenge for manufacturers.

Regional Insights

The Asia Pacific bearing market, valued at USD 54.35 billion in 2024, is projected to reach USD 136.70 billion by 2034, driven by rapid growth in machinery and automotive manufacturing in China, Japan, and India. North America is expected to see long-term growth fueled by rising SUV and hatchback production, with a focus on lightweight vehicle components due to EPA and CAFE standards. Europe’s market is supported by investments in electric and hybrid vehicles and robust automotive industry growth. Emerging economies like South Africa and Brazil are anticipated to record high growth, while mature markets in North America, Europe, and Japan benefit from recovering vehicle production and strong fixed investments.

Don’t Miss Out: Bottled Water Market

Industry Leaders

- SKF

- The Timken Company

- Rexnord Corporation

- MinebeaMitsumi Inc.

- NSK Ltd

Recent Insights

In October 2024, Ormat Technologies Inc., a global leader in geothermal development and technology, introduced the Plain Bearings Turbine (PBT). This innovative turbine features robust hydrodynamic bearings, offering superior reliability and extended lifespan compared to traditional roller bearings, enhancing geothermal power plant efficiency. Similarly, SKF Automotive unveiled its new Hub Bearing Unit (HBU) wheel bearing in the same month. This advanced unit combines two rolling bearings into one, reducing friction by 30% and weight by 10%, improving vehicle efficiency and performance.

Market Segmentation

By Product Type

- Plain Bearing

- Ball Bearing

- Four-point Contact

- Self-aligning

- Deep Groove

- Angular Contact

- Others

- Roller Bearing

- Others

By Type

- Mounted Bearing

- Unmounted Bearing

By Material

- Metal

- Stainless Steel

- Chrome Steel

- Carbon Steel

- Brass

- Others

- Plastic

- Ceramic

By Distribution Channel

- OEM

- Aftermarket

By Size

- 30 to 40

- 41 to 50

- 51 to 60

- 61 to 70

- 70 & above

By Application

- Electrical

- Construction

- Aerospace

- Automotive

- Power Transmission

- Oil & Gas