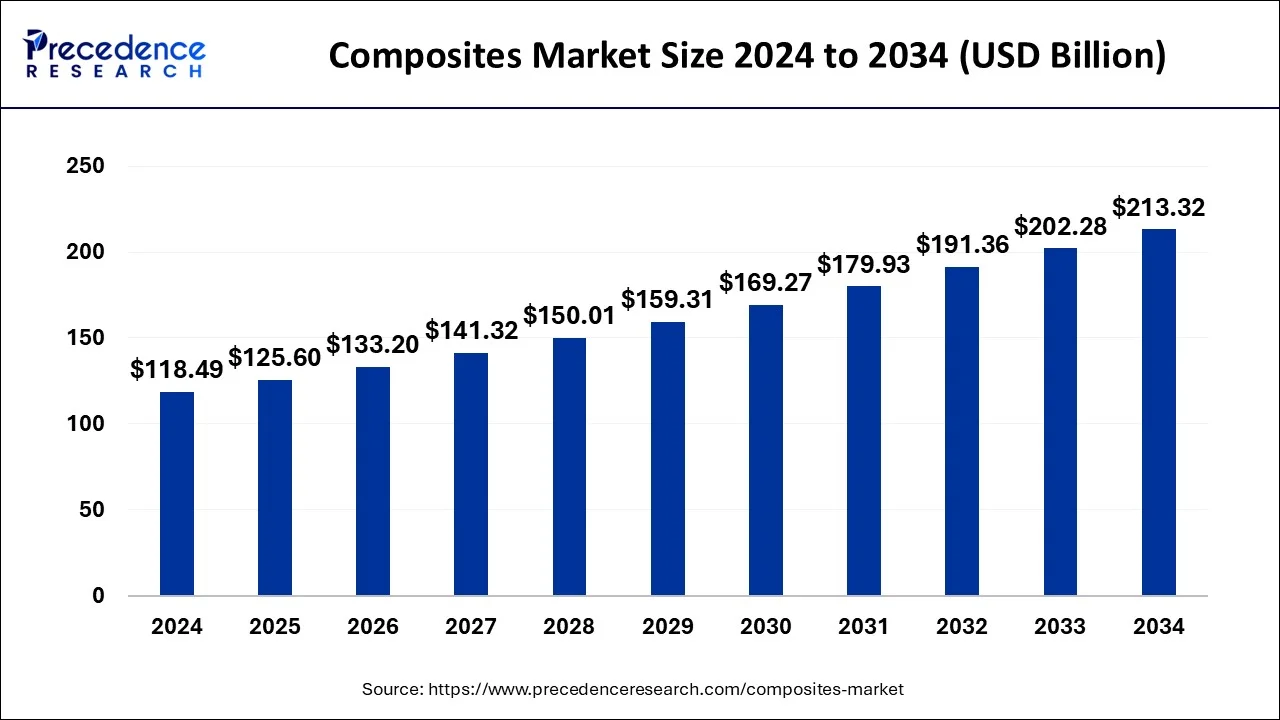

The global composites market is set to grow from USD 118.49B in 2024 to USD 213.32B by 2034, achieving a steady CAGR of 6.05%.

Composites Market Critical Observations

- Asia Pacific led the composites market in 2024, capturing 46% of the market share.

- Glass fiber was the dominant product, contributing 61% to the market.

- The layup process held the largest share among manufacturing methods at 36%.

- The automotive and transportation sector accounted for 22% of the market share in end-use applications.

The global composites market is growing rapidly, fueled by progress in materials and manufacturing processes. Industries such as automotive, aerospace, construction, and renewable energy are leveraging composites like glass fibers, carbon fibers, and natural fibers for their lightweight strength and superior performance. These materials offer durability, design flexibility, and enhanced functionality, making them vital for diverse applications. As sustainability takes center stage, the adoption of eco-friendly composites is on the rise. The market’s future growth will be shaped by ongoing technological advancements and innovative solutions.

Sample Link: https://www.precedenceresearch.com/sample/1018

Market Scope

| Report Highlights | Details |

| Market Size in 2024 | USD 118.49 Billion |

| Market Size in 2025 | USD 125.60 Billion |

| Market Size by 2034 | USD 213.32 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 6.05% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, End User, Resin, Manufacturing Process, Region |

Core Factors

Key factors propelling the composites market include the use of Digital Composite Manufacturing (DCM), which streamlines production by removing physical labor and enabling 3D customization for ideal strength, density, and flexibility. The growing demand for unique design possibilities is also a significant driver, as composites allow for item consolidation and diverse surface textures, offering design solutions beyond traditional materials. These advantages lead to reduced production time, lower maintenance costs, and expanded opportunities across industries.

Potentials

- Growth in the Automotive Sector: The push for lightweight, fuel-efficient vehicles presents a significant opportunity for composites, particularly in the production of car parts such as body panels, interior components, and structural elements.

- Aerospace and Defense: With a constant demand for high-performance materials, composites are crucial for reducing weight and enhancing the strength of aircraft, missiles, and defense equipment, offering a growing market for innovation.

- Renewable Energy: The demand for wind turbines and solar panels is rising, and composites’ lightweight and durable properties make them ideal for these applications, driving opportunities in the renewable energy sector.

- Construction and Infrastructure: As the construction industry looks for stronger, more durable materials, composites offer innovative solutions for building materials, from reinforced concrete to structural beams and facades.

- Sustainability and Eco-Friendly Materials: Increasing demand for sustainable solutions provides a chance for the composite market to expand, with eco-friendly materials and recycling technologies becoming more prevalent.

Obstacles

- High Production Costs: The manufacturing process for composites, especially advanced materials like carbon fiber, is expensive, limiting their widespread adoption in cost-sensitive industries.

- Recycling and Disposal Issues: Recycling composite materials, particularly thermosets, is difficult due to their non-reversible curing process, posing environmental concerns and creating challenges for sustainability.

- Skilled Labor Shortage: The composite industry faces a shortage of skilled workers, including engineers and technicians, which hinders the growth and innovation potential of the market.

- Complex Manufacturing Processes: The production of composites often involves intricate and specialized processes, such as layup and curing, which can increase lead times and result in high operational costs.

- Limited Material Variety: While composites offer excellent properties, the variety of available materials is still limited compared to traditional materials like metals and plastics, limiting design flexibility.

Regional Insights

Asia-Pacific commands the largest share of the composites market in 2024, accounting for 46%, driven by industrial growth, automotive production, and strong demand in construction and aerospace from China, India, and Japan. North America leverages advancements in aerospace, defense, and renewable energy, with the U.S. leading the way in reducing emissions through lightweight materials. Europe sees solid growth in the automotive and aerospace sectors, propelled by sustainability initiatives and stringent regulations. In Latin America, growing construction and industrial activity in Brazil and Mexico fuel market demand, while the Middle East and Africa benefit from significant infrastructure development and construction projects.

Don’t Miss Out: Advanced Composites Market

Industry Leaders

- Hexcel Corporation

- DuPont

- Momentive Performance Materials, Inc.

- Jushi Group Co., Ltd.

- Compagnie de Saint-Gobain S.A

- Weyerhaeuser Company

- Cytec Industries

Recent Insights

In 2022, Owens Corning and Pultron Composites formed a joint venture to produce advanced fiberglass rebar, emphasizing sustainability and high-performance concrete reinforcement. Teijin Automotive Technologies opened a new composites manufacturing facility in China’s Wujin Hi-Tech Industrial Zone. Hexcel Corporation won a long-term contract with Lockheed Martin’s Sikorsky, supplying composite materials for the CH-53K King Stallion helicopter program. At the same time, SGL Carbon rolled out carbon fiber materials and composite solutions tailored for the automotive and industrial sectors.

Market Segmentation

By Product Type

- Glass Fiber

- Carbon Fiber

- Others

By Resin Type

- Thermoplastic

- Thermosetting

- Others

By Manufacturing Process Type

- Injection Molding Process

- Resin Transfer Molding Process

- Pultrusion Process

- Layup Process

- Filament Winding Process

- Compression Molding Process

- Others

By End Use

- Electrical & Electronics

- Automotive & Transportation

- Wind Energy

- Aerospace & Defense

- Pipes & Tanks

- Construction & Infrastructure

- Marine

- Others