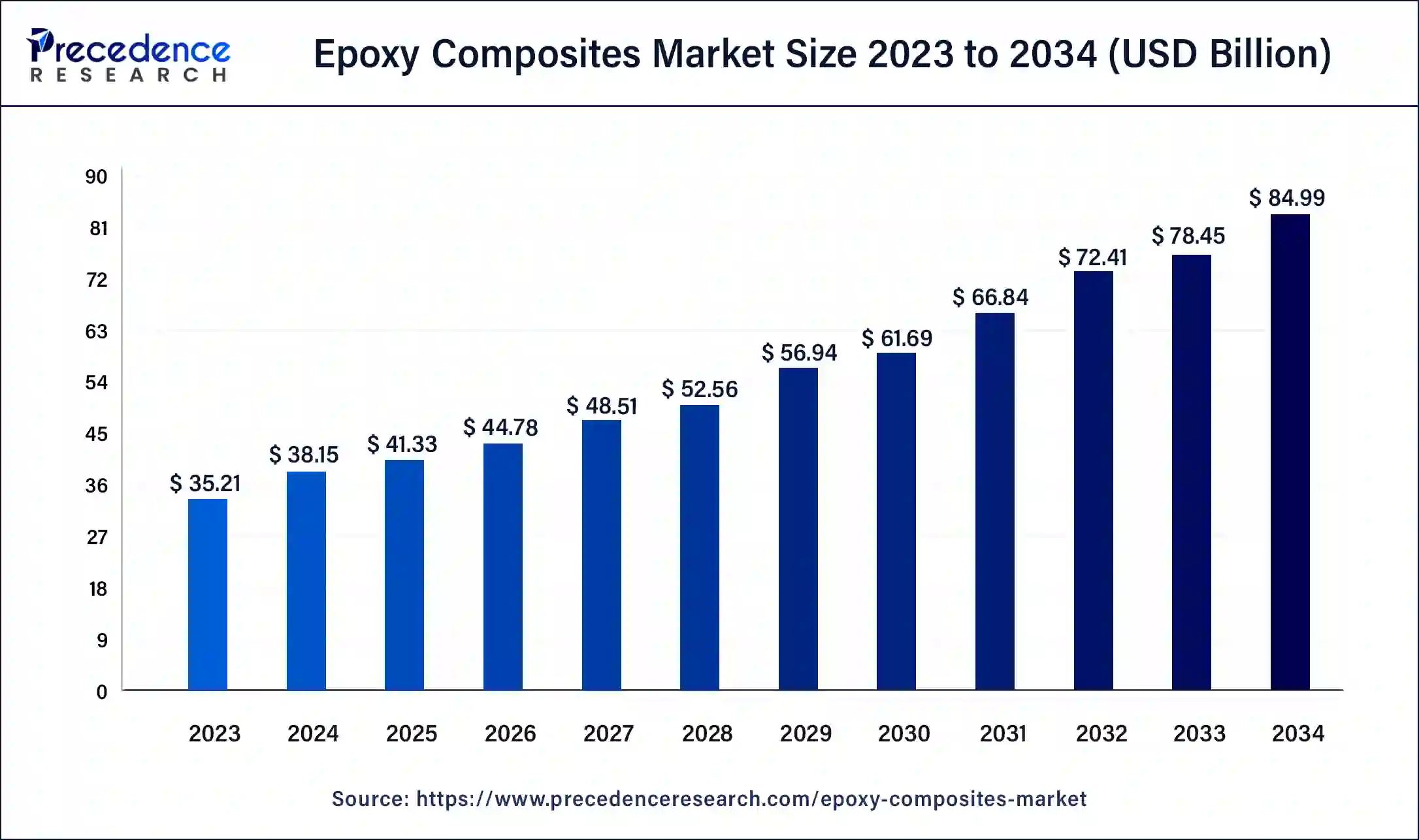

The global epoxy composites market size surpassed USD 35.21 billion in 2023 and is projected to attain around USD 84.99 billion by 2034 with a notable CAGR of 8.34% from 2024 to 2034.

Epoxy composites are a type of advanced material widely used across various industries due to their exceptional mechanical properties, lightweight nature, and resistance to corrosion. These composites are formed by combining epoxy resin with reinforcing fibers such as carbon, glass, or aramid, offering high strength-to-weight ratios and superior durability. Industries such as aerospace, automotive, construction, and electronics utilize epoxy composites extensively for structural components, interiors, and electrical applications.

Get a Sample: https://www.precedenceresearch.com/sample/4679

Epoxy Composites Market Key Points

- Asia Pacific dominated the epoxy composites market with the largest revenue share of 39% in 2023.

- North America is expected to host the fastest-growing market during the forecast period.

- By fiber type, the glass fiber segment has held a major revenue share of 63% of revenue share in 2023.

- By fiber type, the carbon fiber segment is expected to grow at a fastest CAGR of 8.53% during the forecast period.

- By end use, the automotive & transportation segment has generated more than 28% of revenue share in 2023.

- By end use, the aerospace segment is expected to grow at the fastest rate in the market during the forecast period.

Epoxy Composites Market Trends

- Growing Demand in Aerospace and Automotive Industries: Epoxy composites are valued for their lightweight properties and high strength-to-weight ratio, making them ideal for aerospace and automotive applications. As these industries focus more on fuel efficiency and performance, the demand for epoxy composites continues to rise.

- Rising Popularity in Wind Energy: Epoxy composites play a crucial role in wind turbine blades due to their durability and ability to withstand harsh environmental conditions. With the expansion of wind energy installations globally, there’s a significant demand for epoxy composites in this sector.

- Increased Use in Construction: The construction industry is adopting epoxy composites for various applications such as reinforcing concrete structures, repairing infrastructure, and creating lightweight yet strong building materials. This trend is driven by the need for sustainable and resilient construction materials.

- Advancements in Manufacturing Techniques: Innovations in manufacturing processes, including automated layup techniques, resin infusion methods, and 3D printing of epoxy composites, are enhancing production efficiency and reducing costs. These advancements are also enabling complex geometries and customized designs.

- Focus on Sustainability: Environmental concerns are driving the development of sustainable epoxy composites. Manufacturers are exploring bio-based resins and recyclable fibers to reduce the environmental impact of these materials. Regulations promoting sustainable practices further push this trend.

Regional Insights

Regionally, North America and Europe dominate the epoxy composites market, driven by established aerospace and automotive industries, stringent regulatory standards, and robust research and development activities. Asia-Pacific is witnessing rapid growth fueled by expanding construction and electronics sectors in countries like China, India, and Japan. The Middle East and Africa are also emerging markets with increasing infrastructure investments driving demand for epoxy composites in building and construction applications.

Epoxy Composites Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 84.99 Billion |

| Market Size in 2023 | USD 35.21 Billion |

| Market Size in 2024 | USD 38.15 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 8.34% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Fiber Type, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Fiber Type Insights

Epoxy composites utilize a variety of fibers, including carbon fibers, glass fibers, and aramid fibers, among others. Carbon fibers are particularly favored for their high strength and stiffness, making them ideal for aerospace and automotive applications where lightweight materials are crucial. Glass fibers are commonly used in construction and marine industries due to their cost-effectiveness and corrosion resistance. Aramid fibers, known for their exceptional impact resistance and heat stability, find applications in protective gear and ballistic armor.

End-use Insights

The end-uses of epoxy composites span multiple industries. In aerospace, they are used in aircraft components such as wings and fuselages, where lightweight materials are essential for fuel efficiency. Automotive applications include structural parts and interior components, where composites offer weight reduction without compromising strength. In construction, epoxy composites are utilized in bridges, buildings, and pipelines for their durability and resistance to harsh environmental conditions. Electronics benefit from composites’ electrical insulation properties, while sports and leisure industries use them in equipment like tennis rackets and bicycles for enhanced performance. As advancements continue in composite manufacturing and material science, the scope of applications for epoxy composites is expected to expand further across various sectors

Epoxy Composites Market Dynamics

Drivers:

Key drivers of the epoxy composites market include growing investments in infrastructure development, rising demand for lightweight and durable materials in various end-use industries, and increasing adoption of composites for replacing traditional materials like metals. Technological advancements in resin formulations and manufacturing processes are further boosting market growth, enabling manufacturers to meet stringent performance requirements and environmental standards.

Opportunities:

Opportunities in the epoxy composites market lie in expanding applications in renewable energy sectors such as wind energy, where composites are used in turbine blades for their high strength and fatigue resistance. Additionally, the development of electric vehicles is driving demand for lightweight materials, presenting new growth avenues for epoxy composites manufacturers. Moreover, collaborations between research institutions and industry players are expected to lead to innovations in composite materials, offering novel opportunities in niche applications.

Challenges:

Despite its growth prospects, the epoxy composites market faces challenges such as high material costs associated with raw materials like carbon fibers and epoxy resins. Moreover, issues related to recycling and disposal of composite materials pose environmental challenges, necessitating sustainable solutions and recycling technologies. Regulatory complexities and certification requirements also pose challenges for market players, requiring compliance with stringent safety and quality standards across different regions.

Read Also: Clinical Documentation Improvement Market Size, Share, Report by 2034

Epoxy Composites Market Companies

- Axiom Materials.

- Barr day.

- Hexcel Corporation.

- Mitsubishi Chemical Corporation.

- Park Aerospace Corp.

- Sanders Composites.

- SGL Carbon.

Recent Developments

- In July 2024, Solvay launched the epoxy-based CYCOM® EP2190 system, which offers exceptional durability in thick and thin structures together with good in-plane performance in hot/wet and cold/dry situations. The material, which is the company’s new flagship product for aerospace primary structures, competes with existing solutions for wing and fuselage applications in the majority of aviation market segments, from defense and rotorcraft to urban air mobility (UAM) and private and commercial aerospace segments (sub and supersonic).

- In June 2024, With the introduction of its new NE7 low-temperature curing prepreg system, Notus Composites (UAE), the distinguished manufacturer of epoxy prepreg materials, is pleased to announce the newest addition to its high-performance epoxy portfolio. With the completely new Notus NE7 formulation, producers of composites can cure components at as low as 70ËšC, saving energy and opening up more affordable tooling possibilities.

Segment Covered in the Report

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Other Fiber

By End-use

- Automotive & Transportation

- Aerospace & Defense

- Wind Energy

- Electrical & Electronics

- Sporting & Consumer Goods

- Other End-Use (Oil & Gas, Marine, Construction)

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/