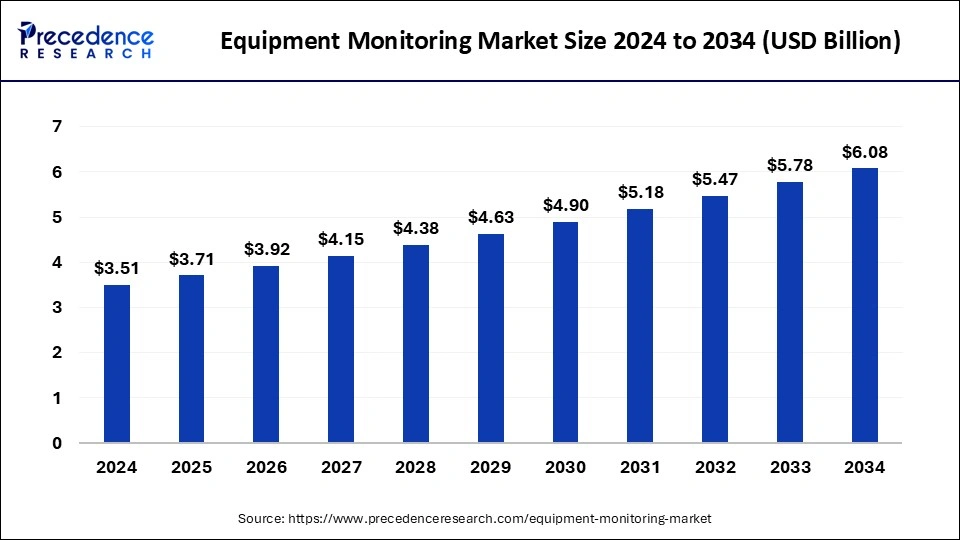

The global equipment monitoring market size reached USD 3.32 billion in 2023 and is expected to surpass around USD 5.78 billion by 2033, expanding at a CAGR of 5.71% from 2024 to 2033.

Equipment Monitoring Market Key Points

- The North America equipment monitoring market size reached USD 1.43 billion in 2023 and is expected to attain around USD 2.51 billion by 2033, poised to grow at a CAGR of 5.78% between 2024 and 2033.

- North America dominated the equipment monitoring market with the largest revenue share of 43% in 2023.

- Europe holds a significant share of the global market.

- By region, Asia Pacific is expected to grow at a significant rate in the market during the forecast period.

- By monitoring type, the vibration monitoring segment dominated the market in 2023.

- By monitoring process, the online equipment monitoring segment is expected to grow at a significant rate in the market during the forecast period.

- By deployment type, the on-premises segment has contributed more than 71% of revenue share in 2023.

- By service offering, the oil & gas segment dominated the market with the largest share in 2023.

The Equipment Monitoring Market is rapidly evolving, driven by the increasing demand for real-time insights into machinery and equipment performance across various industries. Equipment monitoring involves the use of advanced technologies such as sensors, IoT (Internet of Things), AI (Artificial Intelligence), and data analytics to track the condition and performance of equipment. This enables businesses to predict failures, schedule timely maintenance, and optimize operations, ultimately enhancing productivity and reducing downtime.

The market encompasses a wide range of industries including manufacturing, oil and gas, energy and utilities, transportation, and healthcare. The growing trend of digital transformation across these sectors is a significant driver for the adoption of equipment monitoring solutions. As businesses strive to enhance operational efficiency and reduce costs, the demand for sophisticated monitoring systems that provide actionable insights is on the rise.

Get a Sample: https://www.precedenceresearch.com/sample/4596

Growth Factors

Advancements in IoT and Sensor Technologies

One of the primary growth factors for the Equipment Monitoring Market is the rapid advancement in IoT and sensor technologies. These technologies enable continuous monitoring of equipment in real-time, providing crucial data on performance metrics such as temperature, pressure, vibration, and other critical parameters. The integration of IoT with equipment monitoring systems allows for seamless data collection and analysis, leading to improved predictive maintenance capabilities.

Increasing Focus on Predictive Maintenance

Predictive maintenance is becoming a key focus area for many industries as it helps in minimizing unplanned downtime and extending the lifespan of equipment. Equipment monitoring systems play a vital role in predictive maintenance by analyzing data trends and predicting potential failures before they occur. This proactive approach to maintenance not only reduces repair costs but also enhances overall operational efficiency.

Rising Adoption of Cloud Computing

The adoption of cloud computing is significantly impacting the Equipment Monitoring Market. Cloud-based monitoring solutions offer several advantages including scalability, cost-effectiveness, and ease of access to data from anywhere at any time. These solutions enable businesses to store and analyze large volumes of data generated by monitoring systems, facilitating better decision-making and improved maintenance strategies.

Government Regulations and Standards

Government regulations and industry standards aimed at ensuring equipment safety and reliability are also driving the growth of the Equipment Monitoring Market. Compliance with these regulations often requires the implementation of monitoring systems to ensure equipment operates within specified safety and performance parameters. This has led to increased investments in equipment monitoring technologies.

Regional Insights

North America

North America holds a significant share in the Equipment Monitoring Market, primarily due to the presence of major industry players and the high adoption rate of advanced technologies. The region’s strong focus on industrial automation and the implementation of IoT in manufacturing processes are key factors contributing to market growth. Additionally, stringent regulations regarding equipment safety and maintenance standards further drive the adoption of monitoring solutions.

Europe

Europe is another prominent market for equipment monitoring, with countries like Germany, France, and the UK leading the way. The region’s well-established industrial sector and the increasing emphasis on Industry 4.0 are major growth drivers. European companies are increasingly adopting equipment monitoring systems to enhance operational efficiency and comply with regulatory requirements. The automotive and aerospace industries, in particular, are significant contributors to the market’s growth in this region.

Asia-Pacific

The Asia-Pacific region is expected to witness substantial growth in the Equipment Monitoring Market over the coming years. Rapid industrialization, especially in countries like China, India, and Japan, is a major factor driving the demand for monitoring solutions. The growing adoption of IoT and automation technologies in manufacturing processes is also fueling market growth. Additionally, government initiatives to promote smart manufacturing and enhance equipment reliability are creating lucrative opportunities for market players in this region.

Equipment Monitoring Market Scope

| Report Coverage | Details |

| Market Size by 2033 | USD 5.78 Billion |

| Market Size in 2023 | USD 3.32 Billion |

| Market Size in 2024 | USD 3.51 Billion |

| Market Growth Rate from 2024 to 2033 | CAGR of 5.71% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Monitoring Type, Monitoring Process, Deployment Type, Service Offering, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Equipment Monitoring Market Dynamics

Market Drivers

Increasing Demand for Real-time Monitoring

The need for real-time monitoring of equipment performance is a significant driver for the Equipment Monitoring Market. Businesses are increasingly seeking solutions that provide instant insights into equipment health and performance, enabling them to take immediate corrective actions. Real-time monitoring helps in detecting anomalies early, preventing potential failures and reducing downtime.

Growing Emphasis on Operational Efficiency

Enhancing operational efficiency is a top priority for many industries, and equipment monitoring systems play a crucial role in achieving this goal. By providing detailed insights into equipment performance, these systems help businesses optimize their operations, reduce energy consumption, and minimize maintenance costs. The growing emphasis on operational efficiency is thus driving the demand for advanced equipment monitoring solutions.

Rising Awareness about Predictive Maintenance

The increasing awareness about the benefits of predictive maintenance is another key driver for the market. Predictive maintenance involves analyzing data to predict equipment failures and schedule maintenance activities accordingly. Equipment monitoring systems provide the necessary data and analytics capabilities to implement predictive maintenance strategies effectively. This approach not only reduces unplanned downtime but also extends the lifespan of equipment, leading to cost savings.

Technological Advancements

Continuous advancements in technology are significantly impacting the Equipment Monitoring Market. Innovations in sensor technology, IoT, AI, and data analytics are enabling the development of more sophisticated and efficient monitoring systems. These advancements are enhancing the capabilities of equipment monitoring solutions, making them more accurate, reliable, and user-friendly.

Opportunities

Integration of AI and Machine Learning

The integration of AI and machine learning technologies presents significant opportunities for the Equipment Monitoring Market. These technologies can enhance the predictive maintenance capabilities of monitoring systems by enabling advanced data analytics and pattern recognition. AI-powered monitoring solutions can predict equipment failures with higher accuracy, optimize maintenance schedules, and provide actionable insights to improve operational efficiency.

Expansion into New Industries

While the Equipment Monitoring Market is already well-established in industries such as manufacturing and oil and gas, there is significant potential for expansion into new sectors. Industries such as healthcare, transportation, and energy are increasingly adopting equipment monitoring solutions to enhance equipment reliability and performance. The expansion into these new industries presents lucrative growth opportunities for market players.

Development of Cost-effective Solutions

The development of cost-effective equipment monitoring solutions is another key opportunity for the market. While large enterprises can afford advanced monitoring systems, small and medium-sized businesses often face budget constraints. Developing affordable monitoring solutions that cater to the needs of smaller businesses can help market players tap into a wider customer base and drive market growth.

Increasing Adoption of Cloud-based Solutions

The growing adoption of cloud-based equipment monitoring solutions is creating new opportunities for market growth. Cloud-based solutions offer several advantages, including scalability, cost-effectiveness, and remote access to data. These solutions are particularly beneficial for businesses with multiple locations, as they enable centralized monitoring and management of equipment. The increasing adoption of cloud-based solutions is thus driving the demand for equipment monitoring systems.

Challenges

High Initial Investment

One of the primary challenges facing the Equipment Monitoring Market is the high initial investment required for implementing monitoring systems. The cost of sensors, IoT devices, software, and infrastructure can be substantial, particularly for small and medium-sized businesses. The high initial investment can be a barrier to the adoption of equipment monitoring solutions, limiting market growth.

Data Security and Privacy Concerns

Data security and privacy concerns are significant challenges in the Equipment Monitoring Market. The collection and analysis of data from equipment involve handling sensitive information, which can be vulnerable to cyber threats. Ensuring the security and privacy of data is crucial to gain the trust of businesses and promote the adoption of monitoring solutions. Market players need to invest in robust security measures to address these concerns.

Read Also: Carbon Dioxide Removal Market Size to Surpass USD 2,548.29 Mn by 2033

Equipment Monitoring Market Companies

- SKF

- Emerson Electric

- General Electric

- Honeywell International

- National Instruments

- Parker Hannifin Corporation

- Rockwell Automation, Inc.

- Schaeffler AG

- ABB

- Fortive Corporation

- ALS Limited

- Schneider Electric Co.

Recent Developments

- In June 2024, Teledyne FLIR LLC, a defense industry company, announced the launch of the SV89 Vibration Monitoring Solution Kits and FLIR SV88, which assist customers in monitoring critical equipment by continuously detecting faults, alerting to potential defects and future problems and analyzing vibration. The SV88 and SV89 Vibration Monitoring Solution Kits’ multi-communication protocols, IP66 rating, wireless functionality, and rugged design enable customers to make crucial data-driven decisions that prolong the life of expensive equipment by warning of possible problems.

- In May 2024, Datadog, Inc., a company that is focused on developing the monitoring and security platform for cloud applications, revealed the launch of the IT Event Management to its suite of AIOps (artificial intelligence for information technology operations) capabilities. Datadog’s event management feature allows it to intelligently combine, correlate, and enhance all alert events and significant signals from both Datadog and other third-party observability tools into a single, coherent view. By reducing alert fatigue, this technique enables teams to concentrate their efforts and resources on fixing problems.

Segment Covered in the Report

By Monitoring Type

- Vibration Monitoring

- Thermal Monitoring

- Lubrication Monitoring

- Corrosion Monitoring

- Noise Monitoring

- Motor Current Monitoring

- Gps Tracking

- Alarm Monitoring

By Monitoring Process

- Portable Equipment Monitoring

- Online Equipment Monitoring

By Deployment Type

- Cloud

- On-premises

By Service Offering

- Chemicals

- Automotive

- Aerospace & Defense

- Food & Beverages

- Oil & Gas

- Power Generation

- Metals & Mining

- Others (Electronic &Semiconductor, Cement, Paper & Pulp, and Healthcare)

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/