Ophthalmic Packaging Market Size and Growth

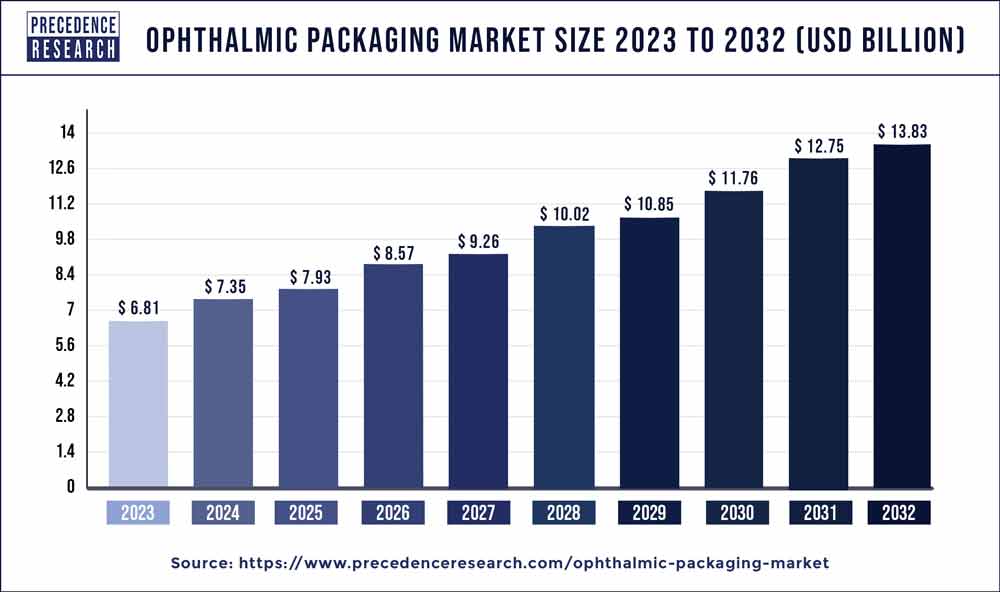

The global ophthalmic packaging market size surpassed USD 6.81 billion in 2023 and is projected to reach around USD 13.83 billion by 2032 with a notable CAGR of 8.2% from 2024 to 2032.

Ophthalmic Packaging Market Statistics

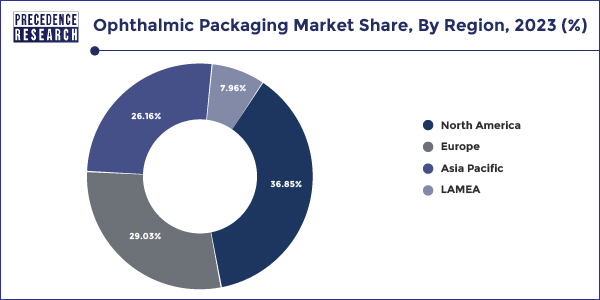

- North America generated more than 36.85% of revenue share in 2023.

- Asia Pacific is expected to expand at the fastest CAGR from 2024 to 2032.

- By Application, the prescription segment registered more than 56.89% of revenue share in 2023.

- By Material, the plastic segment recorded the biggest market share of around 53.84% in 2023.

The Identity and Ophthalmic Packaging Market is experiencing robust growth due to the increasing prevalence of eye disorders and the rising demand for effective packaging solutions in the ophthalmic industry. This market encompasses various types of packaging, including bottles, tubes, blister packs, and pouches, designed to ensure the safety, stability, and efficacy of ophthalmic products such as eye drops, ointments, and surgical instruments. The market is driven by advancements in packaging technologies that enhance product protection, improve patient convenience, and comply with stringent regulatory standards. Additionally, the growing awareness of eye health, coupled with an aging population, is propelling the demand for ophthalmic treatments and, consequently, for efficient packaging solutions.

Get a Sample: https://www.precedenceresearch.com/sample/3072

Regional Insights

The ophthalmic packaging market exhibits varying growth trends across different regions due to factors such as the prevalence of eye disorders, healthcare infrastructure, regulatory frameworks, and consumer awareness. North America holds a significant share of the market, driven by a high incidence of eye diseases, advanced healthcare facilities, and the presence of key market players. The Asia-Pacific region is experiencing rapid growth, propelled by an aging population, increasing disposable incomes, and improving healthcare services, particularly in countries like China and India.

- The U.S. Ophthalmic Packaging market size was estimated at USD 1.55 billion in 2023 and is projected to reach USD 2.99 billion by 2032, growing at a CAGR of 7.5% from 2024 to 2032.

Europe maintains a steady market share due to robust healthcare systems and widespread adoption of advanced ophthalmic treatments. Latin America and the Middle East & Africa are also contributing to market expansion, albeit at a slower pace, with efforts to enhance healthcare accessibility and awareness about eye health. Each region’s unique demographic and economic characteristics shape the demand for ophthalmic packaging, influencing market dynamics and growth prospects.

- According to the World Health Organization, one in six individuals on the globe will be 60 or older by 2030. By this point, there will be 1.4 billion people over the age of 60, up from 1 billion in 2020. The number of individuals in the world who are 60 or older will double (to 2.1 billion) by 2050. Between 2020 and 2050, the number of people 80 or older is projected to treble, reaching 426 million.

- According to the World Glaucoma Association, in 2020, glaucoma will affect 79.6 million people, according to estimates. In 2040, there will probably be 111.8 million people in the world. At least 50 percent of glaucoma sufferers are not aware of their condition. 90% of glaucoma cases in certain underdeveloped nations go undiagnosed.

Ophthalmic Packaging Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2032 | CAGR of 8.2% |

| Market Size in 2023 | USD 6.81 Billion |

| Market Size by 2032 | USD 13.83 Billion |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2032 |

| Segments Covered | By Material, By Product Type, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Ophthalmic Packaging Market Segments

Material Insights

Plastic: Plastic is the most widely used material in ophthalmic packaging due to its versatility, durability, and cost-effectiveness. Plastics like polyethylene, polypropylene, and polyethylene terephthalate (PET) are commonly used for making bottles, caps, and blister packs. These materials are lightweight, provide excellent protection against contamination, and are easy to mold into various shapes and sizes, which is essential for accommodating different types of ophthalmic products. Moreover, plastic packaging offers good barrier properties against moisture and oxygen, ensuring the stability and efficacy of the medication.

Glass: Glass is another significant material used in ophthalmic packaging, particularly for products that require superior protection against environmental factors. Glass vials and bottles are preferred for their excellent chemical resistance, non-reactivity, and ability to maintain product integrity over long periods. Although heavier and more fragile than plastic, glass is often used for high-value ophthalmic solutions and drugs that are sensitive to plastic components. The transparency of glass also allows for easy inspection of the contents, which is an added advantage for quality control.

Product Type Insights

Bottles: Bottles are a staple in ophthalmic packaging, used primarily for eye drops and liquid solutions. They are designed to be user-friendly, with droppers or nozzle caps that allow precise dispensing of the medication. The materials used for bottles are typically plastic or glass, chosen based on the product’s sensitivity and storage requirements. The design of ophthalmic bottles often includes tamper-evident features and child-resistant caps to enhance safety and compliance.

Blister Packs: Blister packs are extensively used for solid ophthalmic products such as tablets and capsules. They offer excellent protection against environmental factors like moisture and oxygen, ensuring the long-term stability of the medication. Blister packs are typically made from a combination of plastic and aluminum foil, providing a secure and tamper-evident packaging solution. They also offer convenience to consumers through easy-to-use push-through or peel-off designs.

Application Insights

Eye Drops: Eye drops represent the largest segment in the ophthalmic packaging market. The packaging for eye drops is primarily in the form of plastic or glass bottles with dropper caps, which allows for controlled and hygienic dispensing. This segment requires packaging that ensures sterility and protection against microbial contamination. The design often includes features to prevent overuse and maintain the integrity of the medication over its shelf life.

Ointments: Ointments and gels are another critical application in the ophthalmic packaging market. These products are typically packaged in metal or plastic tubes that protect the contents from air and light. The packaging needs to be easy to use, providing precise control over the amount of product dispensed. The materials used for ointment packaging must be compatible with the formulation to prevent any interaction that could affect the efficacy of the medication.

Read Also: Oilfield Chemicals Market Size to Hit USD 45.79 Bn By 2032

Ophthalmic Packaging Market Dynamics

Drivers

Several key drivers are fueling the growth of the Identity and Ophthalmic Packaging Market. Firstly, the increasing incidence of eye diseases such as glaucoma, cataracts, and age-related macular degeneration is leading to a higher consumption of ophthalmic products, thereby boosting the demand for specialized packaging. Secondly, technological advancements in packaging materials and techniques, such as tamper-evident and child-resistant packaging, are enhancing product safety and compliance with regulatory requirements. Thirdly, the rising trend of self-medication and the availability of over-the-counter ophthalmic products are increasing the need for user-friendly packaging that ensures proper dosage and easy application. Lastly, the expansion of the pharmaceutical and healthcare industries, especially in emerging markets, is creating significant opportunities for growth in the ophthalmic packaging sector.

Opportunities

The Identity and Ophthalmic Packaging Market presents several lucrative opportunities for growth and innovation. One major opportunity lies in the development of sustainable and eco-friendly packaging solutions. With growing environmental concerns and regulatory pressures to reduce plastic waste, manufacturers are exploring biodegradable and recyclable materials for ophthalmic packaging. Another opportunity is the integration of smart packaging technologies, such as QR codes and NFC tags, which can provide patients with detailed information about the product, usage instructions, and reminders for medication schedules. Additionally, the increasing focus on personalized medicine and targeted drug delivery systems is driving the demand for customized packaging solutions that cater to specific patient needs and treatment protocols. Expanding into untapped markets, particularly in developing regions with rising healthcare expenditure and improving access to eye care services, also offers significant growth potential.

Challenges

Despite the positive outlook, the Identity and Ophthalmic Packaging Market faces several challenges. One of the primary challenges is the stringent regulatory landscape governing ophthalmic products and their packaging. Compliance with various regional and international standards requires continuous investment in research and development, quality control, and documentation, which can be resource-intensive. Another challenge is the high cost of advanced packaging materials and technologies, which may impact the pricing and affordability of ophthalmic products. Additionally, ensuring the compatibility of packaging materials with ophthalmic formulations to prevent contamination, degradation, or interactions poses a technical challenge. The market also needs to address issues related to counterfeiting and product tampering, which can compromise patient safety and brand integrity. Lastly, the increasing competition among market players necessitates constant innovation and differentiation to maintain a competitive edge.

Recent Development:

- In July 2021, by opening an office in Baldwin, Wisconsin, Nolato expanded its geographic reach. The business would increase its manufacturing and storage capabilities to meet the demands of medical products as a result of this development. The extension was also designed to support the manufacturing of diagnostic tools and components for pharmaceutical drugs.

- In August 2021, a unique healthcare lidding technology was revealed by Amcor. Combination goods, which have two or more controlled components, would take advantage of the technology.

- In October 2020, DropControl, the most modern type of drug dispenser, was introduced by Gerresheimer. In an ophthalmic context, this solution is appropriate for medications with an exceptionally low solids content.

- In September 2021, Amcor collaborated with Michigan State University’s Department of Packaging and contributed $10 million to build a pipeline for a more environmentally friendly packaging sector.

- In August 2021, the BD COR System has been made available in the United States by Becton Dickinson (BD). This completely autonomous diagnostic technology raises the bar for diagnosing infections and diseases.

Ophthalmic Packaging Market Companies

- Amcor

- West Pharmaceutical Services, Inc.

- Gerresheimer AG

- SCHOTT AG

- AptarGroup, Inc.

- Akorn, Inc.

- Johnson & Johnson Vision

- Mitotech, SA

- Bausch & Lomb Incorporated

- AERIE PHARMACEUTICALS, INC.

- Novartis AG

- Merck Sharp & Dohme Corp.

- Bayer AG

- F. Hoffmann-La Roche Ltd.

- ALLERGAN

- Santen Pharmaceutical Co.

- Teva Pharmaceutical Industries Ltd.