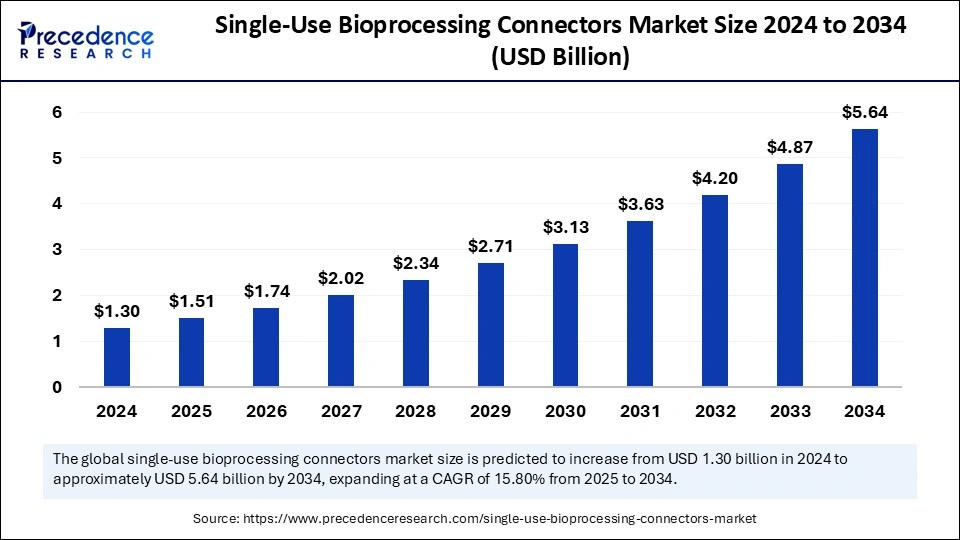

The single-use bioprocessing connectors market worldwide is expected to expand from USD 1.30 billion in 2024 to around USD 5.64 billion by 2034, with a CAGR of 15.80%.

Single-Use Bioprocessing Connectors Market Critical Observations

- North America led the market by holding the largest market share of 48% in 2024.

- Asia Pacific is expected to grow at the fastest CAGR of 17% over the forecast period.

- By product, the aseptic connectors segment held a major market share of 66% in 2024.

- By product, the conventional connectors segment is anticipated to grow at the fastest rate over the forecast period.

- By application, the upstream bioprocessing segment contributed the highest market share of 46% in 2024.

- By end use, the biopharmaceutical and pharmaceutical companies segment held the largest market share of 45% in 2024.

- By end use, the CMOs and CROs segment is projected to grow at the fastest rate during the forecast period.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 5.64 Billion |

| Market Size in 2025 | USD 1.51 Billion |

| Market Size in 2024 | USD 1.30 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 15.80% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Application, End Use, and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. |

Core Factors

One of the primary drivers of the single-use bioprocessing connectors market is the rapid expansion of the biopharmaceutical industry. The increasing demand for biologics, including monoclonal antibodies, vaccines, and biosimilars, has fueled the need for efficient and scalable production systems. Single-use bioprocessing connectors enable manufacturers to streamline operations by reducing cross-contamination risks, eliminating the need for extensive cleaning, and enhancing process efficiency. The rising prevalence of infectious diseases, along with the growing focus on personalized medicine, has further accelerated the adoption of single-use technologies.

Another key factor driving market growth is the cost-effectiveness of single-use systems compared to traditional stainless-steel equipment. By minimizing labor-intensive cleaning processes and reducing the risk of batch failures, these connectors contribute to lower operational costs. Additionally, the increasing adoption of automation and digitalization in biomanufacturing is expected to drive demand for advanced, user-friendly connectors that support seamless integration with modern bioprocessing systems.

Potentials

The expanding scope of single-use bioprocessing in emerging markets presents a significant growth opportunity for industry players. As biopharmaceutical production scales up in regions such as Asia-Pacific and Latin America, the demand for cost-effective and flexible manufacturing solutions is rising. Countries like China and India are witnessing increased investment in biomanufacturing infrastructure, creating a favorable environment for market expansion. Furthermore, the ongoing research and development efforts in regenerative medicine, gene therapies, and cell-based treatments are driving the need for specialized single-use components.

The integration of smart and connected technologies in bioprocessing is another promising opportunity. The development of intelligent connectors with real-time monitoring capabilities can enhance process control and compliance with regulatory requirements. Additionally, strategic collaborations between biopharma companies and single-use technology providers can further accelerate innovation and market penetration. As sustainability concerns grow, manufacturers focusing on developing eco-friendly and recyclable single-use connectors will likely gain a competitive edge in the industry.

Obstacles

Despite the numerous advantages of single-use bioprocessing connectors, certain challenges hinder market growth. One of the primary concerns is the environmental impact associated with single-use plastic waste. The increasing adoption of disposable bioprocessing components has raised sustainability issues, prompting regulatory bodies and industry players to explore alternative materials and recycling initiatives. Another challenge is the risk of supply chain disruptions, particularly during high-demand situations such as the COVID-19 pandemic. The reliance on specific raw materials and manufacturing capacities can lead to production bottlenecks, affecting product availability and pricing.

Compatibility and standardization issues also pose challenges, as different biopharma companies require customized solutions that align with their unique processes. Ensuring regulatory compliance and validation for new single-use connectors is another hurdle, as the industry must adhere to stringent guidelines set by agencies such as the FDA and EMA. Additionally, concerns over extractables and leachables from single-use plastics continue to be a topic of discussion, requiring manufacturers to invest in advanced material research and rigorous testing procedures.

Regional Insights

North America holds a dominant position in the single-use bioprocessing connectors market, driven by a strong biopharmaceutical industry and significant investments in advanced biomanufacturing technologies. The United States, in particular, is home to major biopharma companies and contract manufacturing organizations (CMOs) that are increasingly adopting single-use systems for enhanced operational efficiency. Europe is another key region, with countries such as Germany, the United Kingdom, and France leading in bioprocessing innovations and regulatory advancements.

The presence of stringent quality standards and government support for biopharma research further propels market growth in the region. The Asia-Pacific market is witnessing rapid expansion due to increasing biopharmaceutical production in China, India, South Korea, and Japan. The growing demand for affordable healthcare solutions, coupled with government initiatives to boost domestic biomanufacturing, is driving the adoption of single-use technologies. Latin America and the Middle East & Africa are emerging markets with untapped potential, as investments in pharmaceutical infrastructure and regulatory harmonization efforts continue to rise. These regions are expected to offer lucrative growth opportunities for market players looking to expand their global footprint.

Don’t Miss Out: Renal Failure Treatment Market

Industry Leaders

- Sartorius AG

- Merck KGaA

- Danaher

- Saint-Gobain

- Colder Products Company (Dover Corporation)

- Liquidyne Process Technologies, Inc.

- Foxx Life Sciences

- Watson-Marlow Fluid Technology Solutions

Recent Insights

The single-use bioprocessing connectors market has seen notable developments in recent years, reflecting the growing industry focus on innovation and efficiency. Several key players have launched new product lines to enhance the performance and scalability of single-use systems. For example, leading bioprocessing solution providers have introduced advanced connectors with improved sterility assurance, leak-proof designs, and enhanced material compatibility. Strategic collaborations and mergers have also played a vital role in shaping the market landscape. Major biopharma companies and contract manufacturers have partnered with single-use technology providers to accelerate bioprocessing efficiency and scalability.

Regulatory agencies have also been actively updating guidelines to ensure the safety and reliability of single-use systems. In response to sustainability concerns, industry leaders are exploring biodegradable and recyclable alternatives for single-use connectors. Additionally, digital transformation in bioprocessing has led to the development of smart connectors equipped with monitoring sensors, enabling real-time data tracking and predictive maintenance. With continued advancements and investments, the single-use bioprocessing connectors market is expected to witness robust growth, catering to the evolving needs of the global biopharmaceutical industry.

Market Segmentation

By Product

- Aseptic Connectors

- Conventional Connectors

By Application

- Upstream Bioprocessing

- Downstream Bioprocessing

- Fill-finish Operations

By End Use

- Biopharmaceutical & Pharmaceutical Companies

- CROs & CMOs

- Academic & Research Institutes

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa