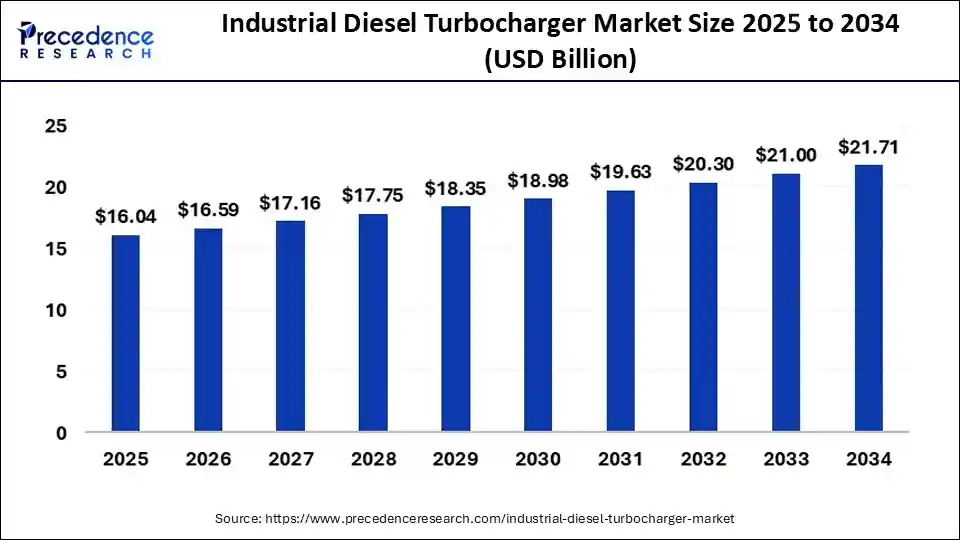

The industrial diesel turbocharger industry is anticipated to rise from USD 15.51 billion in 2024 to approximately USD 21.71 billion by 2034, with an annual growth rate of 3.42%.

The Industrial Diesel Turbocharger Industry Critical Observations

- Asia Pacific dominated the industrial diesel turbocharger market with the largest share of 40% in 2024.

- North America is expected to grow at a significant rate over the forecast period.

- By engine type, the diesel engines segment led the global market in 2024.

- By engine type, the internal combustion engine segment is estimated to grow fastest over the forecast period.

- By sales channel, the OEM sales segment held the largest market share in 2024..

- By sales channel, the direct sales segment is expected to grow at the fastest rate over the forecast period.

- By component type, the compressors segment dominated the market in 2024.

- By component type, the turbine segment is expected to grow rapidly over the projected period.

- By application, the power generation segment dominated the market in 2024.

- By application, the marine application segment is expected to grow at a significant rate over the forecast period.

The industrial diesel turbocharger market is experiencing steady growth, driven by the rising demand for fuel efficiency, increased industrialization, and advancements in turbocharging technology. Turbochargers play a critical role in enhancing the performance of diesel engines by improving combustion efficiency and reducing emissions. Industries such as marine, construction, mining, oil & gas, and power generation rely heavily on diesel-powered machinery, which has fueled the demand for turbochargers to boost engine efficiency and meet stringent environmental regulations.

As of 2024, the global industrial diesel turbocharger market was valued at approximately USD 15.51 billion and is projected to reach around USD 21.71 billion by 2034, growing at a CAGR of 3.42%. The increasing focus on sustainability and regulatory mandates aimed at curbing carbon emissions are accelerating the adoption of advanced turbocharging solutions. Additionally, the push toward higher power output and lower fuel consumption in industrial applications is further driving innovation in turbocharger technology.

The shift toward downsized diesel engines with higher power outputs has also contributed to the growing demand for efficient turbocharging systems. Modern turbochargers are being designed with lightweight materials, improved aerodynamics, and electronic controls to enhance engine responsiveness and durability. As industries look to optimize operational efficiency, the adoption of high-performance diesel turbochargers is expected to rise significantly over the next decade.

Sample Link: https://www.precedenceresearch.com/sample/5717

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 21.71 Billion |

| Market Size in 2025 | USD 16.04 Billion |

| Market Size in 2024 | USD 15.51 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 3.42% |

| Dominated Region | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Engine Type, Component Type, application, Sales Channel and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Core Factors

One of the primary drivers of the industrial diesel turbocharger market is the increasing emphasis on fuel efficiency and emissions reduction. Governments and regulatory bodies worldwide are implementing stringent emissions norms, such as EURO VI, EPA Tier 4, and China VI, compelling industries to adopt cleaner and more efficient diesel engines. Turbochargers help meet these requirements by enabling better air-fuel mixing, improving combustion, and reducing nitrogen oxide (NOx) and particulate matter emissions.

The growing demand for industrial equipment with high power output and lower fuel consumption is also fueling market expansion. Diesel engines power a wide range of industrial applications, including marine vessels, construction equipment, power plants, and mining machinery, where efficiency and reliability are crucial. Turbochargers enable these engines to operate more efficiently, reducing operational costs and improving productivity.

Technological advancements in turbocharger design and materials are further propelling market growth. The introduction of variable geometry turbochargers (VGTs), twin-scroll turbochargers, and electric-assisted turbochargers is enhancing engine responsiveness, optimizing fuel efficiency, and minimizing turbo lag. These innovations cater to industries that require robust, high-performance engines while ensuring compliance with environmental standards.

Potentials

The increasing adoption of hybrid and electrified industrial machinery presents new opportunities for the industrial diesel turbocharger market. While the transition to fully electric equipment is gradual, many industries are integrating hybrid diesel-electric powertrains, where turbochargers continue to play a crucial role in boosting engine efficiency. The development of turbocharging solutions tailored for hybrid applications is expected to create growth avenues for market players.

The rise in infrastructure development projects and industrial expansion, particularly in emerging economies, is another major opportunity. Countries in Asia-Pacific, the Middle East, and Latin America are witnessing rapid industrialization, increasing the demand for heavy machinery and diesel-powered equipment. As a result, manufacturers are investing in cost-effective, high-performance turbochargers to cater to these growing markets.

The shift toward aftermarket turbocharger solutions is also gaining traction. With industrial equipment requiring regular maintenance and replacements, the demand for remanufactured and performance-upgraded turbochargers is rising. Many businesses are opting for aftermarket turbocharging solutions to extend the operational life of their diesel-powered machinery while maintaining performance and fuel efficiency.

Obstacles

Despite its growth potential, the industrial diesel turbocharger market faces several challenges, including fluctuating raw material prices. Turbocharger components, such as turbine wheels, compressor housings, and high-temperature-resistant alloys, are often subject to price volatility, which can impact manufacturing costs and profitability. Rising commodity prices, particularly for nickel, aluminum, and titanium, pose a challenge for market stability.

The increasing adoption of alternative powertrain technologies, such as battery-electric and hydrogen fuel cell systems, poses a potential threat to the diesel turbocharger market. Governments and industries are investing heavily in sustainable energy solutions, and while diesel-powered equipment remains dominant, the gradual shift toward zero-emission technologies could impact long-term demand for turbochargers.

Stringent regulatory approvals and testing requirements also present hurdles for market players. Turbochargers must comply with various emission standards, durability tests, and safety regulations, which can extend product development cycles and increase compliance costs. Meeting these requirements while ensuring optimal performance remains a challenge for manufacturers looking to introduce new turbocharging solutions.

Regional Insights

North America holds a significant share in the industrial diesel turbocharger market, driven by the strong presence of industries such as mining, construction, oil & gas, and power generation. The region’s strict emissions regulations and the need for energy-efficient industrial machinery have accelerated the adoption of advanced turbocharger technologies. Additionally, the growing focus on remanufactured turbochargers and aftermarket services is boosting market growth in this region.

Europe is another key market, with countries like Germany, France, and the UK at the forefront of turbocharger innovation. The region’s strict EURO VI and Stage V emissions regulations have compelled industries to adopt high-efficiency turbochargers for compliance. Europe is also witnessing an increasing trend toward hybrid diesel-electric industrial machinery, further driving demand for customized turbocharging solutions.

The Asia-Pacific region is projected to witness the fastest growth, owing to rapid industrialization and infrastructure development in countries such as China, India, and Japan. The rising demand for construction and mining equipment, coupled with increasing government investments in energy and transportation sectors, is driving the adoption of high-performance diesel engines with turbochargers. China, in particular, is a major manufacturing hub for turbocharger components, making it a key contributor to market expansion.

Latin America, the Middle East, and Africa are emerging markets with significant potential for growth. Increasing investments in oil & gas exploration, mining projects, and heavy-duty construction activities are driving the demand for industrial diesel engines equipped with turbochargers. Governments in these regions are also implementing environmental regulations, encouraging the adoption of fuel-efficient turbocharging solutions.

Don’t Miss Out: Automotive Aftermarket

Industry Leaders

- Cummins

- Turbo Energy

- KTT

- Kangyue

- BorgWarner

- K turbocharger

- Weichai Power

- Mitsubishi Heavy Industries

Recent Insights

The industrial diesel turbocharger market has witnessed several noteworthy developments, particularly in technological advancements and strategic collaborations. Manufacturers are focusing on developing electric-assisted turbochargers (EATs), which integrate electric motors to eliminate turbo lag and improve fuel efficiency. This innovation is gaining traction among industries seeking improved power delivery and lower emissions.

Leading turbocharger manufacturers are expanding their production facilities and R&D centers to cater to the rising global demand. Companies are investing in lightweight materials, aerodynamic turbine designs, and smart turbocharger systems that incorporate digital sensors for real-time performance monitoring. These advancements are enhancing engine efficiency and reducing maintenance costs for industrial users.

The aftermarket turbocharger segment is also seeing increased competition, with many companies launching remanufactured turbochargers and performance upgrade kits. This trend is particularly strong in regions where industries seek cost-effective solutions to extend the operational life of their diesel-powered machinery.

Strategic mergers and acquisitions are shaping the competitive landscape, with major turbocharger manufacturers acquiring smaller firms specializing in high-performance turbo technologies. These acquisitions are enabling companies to expand their product portfolios and strengthen their global market presence.

Market Segmentation

By Engine Type

- Internal Combustion Engine

- Diesel Engine

- Natural Gas Engine

- Dual Fuel Engine

- Heavy Fuel Engine

By Component Type

- Bearing Systems

- Compressor

- Turbine

- Wastegate

- Actuators

By Application

- Marine

- Power Generation

- Construction Equipment

- Mining

- Agricultural Equipment

By Sales Channel

- Direct Sales

- Distributor Sales

- Online Sales

- OEM Sales

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa