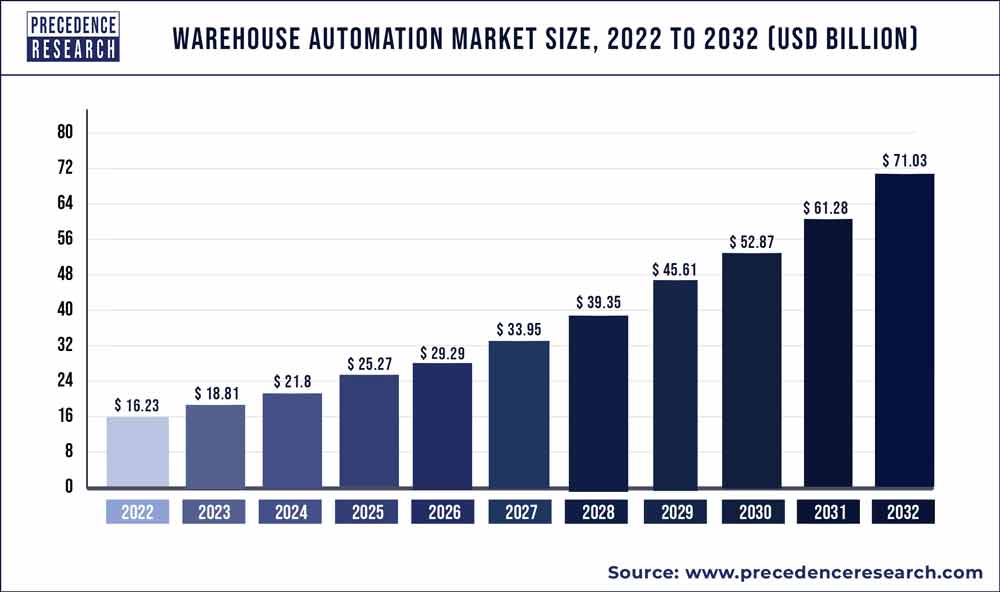

The global warehouse automation market size was valued at USD 16.23 billion in 2022 and is expected to achieve around USD 71.03 billion by 2032, growing at a CAGR of 15.91% during the forecast period from 2023 to 2032.

Warehouse Automation Market Key Insights:

- North America is expected to maintain its dominance in the warehouse automation market during the forecast period.

- By type, the warehouse system segment shows notable growth in the warehouse automation market.

- By component, the hardware segment dominated the global market with 80% of revenue share in 2022.

- By technology, the automated storage and retrieval system segment dominated the global market.

- By application, the e-commerce segment shows significant growth.

- By end-user, the manufacturers segment shares the maximum CAGR during the projection period.

The latest technologies are available to enhance the throughput of inside operations of warehouses, relying on robots, artificial intelligence (AI), and big data. Warehouse automation facilitates tools that improve productivity, minimize errors due to manual product handling, maximize efficiency, optimize throughput processes, provide a safe environment, and avoid stockouts. Autonomous robots are employed at warehouses to perform tasks such as picking and sorting items, transporting goods within the warehouse, and even packing and shipping orders.

Europe is projected to become another attractive marketplace for warehouse automation, driven by the growing adoption of industrial automation and control solutions in the region. Warehouse automation is crucial in optimizing supply chain processes by improving inventory management, order accuracy, and shipment tracking, which helps companies meet client demands while reducing costs and enhancing competitiveness.

Latin America is expected to witness a noticeable growth during the forecast period. The availability of advanced technologies, such as robotics, artificial intelligence, the Internet of Things (IoT), and cloud computing, has contributed to the growth of warehouse automation in Latin America. These technologies enable real-time monitoring, predictive analytics, and seamless integration across various warehouse systems.

Warehouse Automation Market Report Highlights

- By type, the warehouse systems segment leverages big data analytics and AI algorithms to analyze vast amounts of data collected from various sources, which include sensors, machines, and software systems.

- By component, the hardware segment is the most lucrative segment of the market, this improves order fulfillment speed and accuracy, resulting in higher customer satisfaction.

- By technology, automated storage and retrieval systems segment leads the market, it eliminates manual handling and reduces human errors, resulting in faster and more accurate order fulfillment. It maximizes the use of vertical space, allowing for high-density storage and potentially reducing the footprint required for warehousing operations.

- By application, the e-commerce segment is expected to be the most attractive in the market. Warehouse automation accelerates order fulfillment processes. This system can pick, pack, and sort items faster than manual labor, reducing order processing time. This speed is crucial in meeting customer expectations for fast shipping and delivery.

- By end-users, the manufacturing segment is expected to carry the largest share of the market. Industrial robots are used for material handling, pick and place, assembly, and packaging tasks. They can work autonomously or in collaboration with humans.

Warehouse Automation Market Dynamics

Driver: Rising adoption of robotics in warehousing

Warehouse operations can be physically demanding and potentially hazardous for workers. By deploying robots for tasks involving heavy lifting, repetitive motions, or exposure to dangerous environments, companies can minimize the risk of workplace injuries and enhance employee safety. Robotics in warehousing can be integrated with other technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These integrations enable robots to gather and analyze data, make autonomous decisions, and collaborate with other warehouse systems, resulting in a more interconnected and intelligent warehousing ecosystem. Robots designed for warehousing are often compact and can operate in narrow spaces.

They can be used to maximize the utilization of available warehouse space by efficiently navigating through aisles, stacking inventory vertically, and optimizing storage configurations. Robots can work tirelessly and consistently, improving productivity in warehousing operations. They can perform repetitive tasks much faster than humans, leading to increased throughput and shorter order fulfillment times which can be particularly beneficial in e-commerce fulfillment centers that handle large orders.

Read Also: Video Streaming Market Size To Grow USD 1,721.4 Billion by 2030

Restraint: Lack of skilled professionals

Warehouse automation technologies require skilled professionals with the expertise to design, integrate, and implement automation systems effectively. The lack of skilled workers can lead to challenges in deploying automation solutions efficiently and may result in delays or inefficiencies during the implementation process.

Proper training is crucial for operating and maintaining automated warehouse systems. Skilled professionals are vital in training other employees to use and interact with automation technologies effectively. The need for experienced trainers can hinder knowledge transfer and make it challenging for workers to adapt to new technologies, resulting in decreased productivity and increased error rates.

Skilled professionals in the warehouse automation field contribute to innovation by developing new technologies and solutions. They play a vital role in keeping up with the latest advancements and adapting them to the specific needs of warehouses. A shortage of skilled workers may slow innovation and limit the industry’s ability to adopt emerging technologies, potentially putting businesses at a disadvantage compared to their competitors.

Opportunity: Increasing research and development activities

Research and development focus on developing automation solutions tailored to industry needs and requirements. This customization enables companies to address unique challenges in their operations, resulting in optimized workflows, inventory management, and order processing. Customized automation solutions offer a competitive edge and opportunities for differentiation in the market. While automation may replace some manual tasks, it also creates opportunities for upskilling and job creation. Research and development activities lead to new roles, such as automation engineers, data analysts, and system integrators. Skilled professionals can find employment in designing, implementing, and maintaining automation systems, ensuring the smooth functioning of warehouse operations.

Research and development aim to streamline warehouse processes, reduce manual labor, and minimize errors. By developing innovative automation solutions, companies can achieve higher efficiency levels, optimize resource utilization, and improve overall operational performance, opening cost savings opportunities, faster order fulfillment, and enhanced customer satisfaction. It promotes the development of eco-friendly solutions. Automated systems can optimize energy consumption, reduce waste, and minimize carbon emissions. By incorporating sustainable practices into their operations, companies can seize opportunities to reduce costs, enhance brand reputation, and meet the growing demand for environmentally conscious business practices.

Challenge: High upfront costs

Implementing warehouse automation systems requires significant equipment, software, and infrastructure investment. The initial costs are high, especially for smaller businesses, which can be a barrier to entry for some companies. Integrating different automation components and programming them together requires specialized expertise. The costs associated with integrating various systems, configuring software, and ensuring compatibility can be significant. Implementing automation requires modifying the existing warehouse infrastructure to accommodate the new equipment, which may involve structural changes, electrical upgrades, or installing new systems such as automated guided vehicles or robotic workstations. Such services or repairs may require high upfront costs and can be challenging for the market’s growth.